Need smaple of "Tourmaline heating cloth fabric modifier Zirconium carbide hot cathode material raw materials" please contact Ms.Rachel via we-chat or whatsapp

We would like offer the favourable unit cost to you at earliest time, please kindly inform your requests: puirity, Total carbon, Free carbon, O content, Zr Content.

We could make the powder as customer's own formula or demand if below two grades are not suitable for you application.

*Particle size and chemical composition are modified on request*

Below are our common and hot sale grade of ZrC powder, almost choose the 0.8um particle size.

| APS (FSSS) | Purity | Total Carbon | Free Carbon | O content | N Conent | Hf Content |

| 3-5um | ≥ 99.5% | 11.2%-11.6% | ≤0.36% | 0.35% | 0.05% | 1.5% |

0.8-1.5um | ≥ 99.5% | 11.2%-11.6 | ≤0.35% | 0.65% | 0.05% | 1.5% |

Parameters of Carbide powder:

Parameters of Carbide powder:

GRADE | CHEMICAL COMPOSITION(max,%) |

|

Total

carbon | Free

carbon | Impurities(max,%) |

|

|

| Nb | Fe | Si | O | N | Na | K | Ca |

| ZrC | ≥11.2 | ≤0.40 | 0.01 | 0.05 | 0.05 | 0.5 | 0.1 | 0.01 | 0.005 | 0.01 |

| HfC | ≥6.15 | ≤0.30 | 0.005 | 0.05 | 0.005 | 0.5 | 0.05 | 0.005 | 0.005 | 0.05 |

| TaC | ≥6.20 | ≤0.10 | 0.1 | 0.05 | 0.01 | 0.15 | 0.02 | 0.005 | 0.005 | 0.01 |

| NbC | ≥11.1 | ≤0.15 | --- | 0.01 | 0.01 | 0.3 | 0.02 | 0.005 | 0.005 | 0.01 |

| VC | ≥17.7 | ≤0.5 | 0.01 | 0.05 | 0.01 | 0.5 | 0.1 | 0.01 | 0.005 | 0.01 |

| Cr3C2 | ≥12.8 | ≤0.30 | 0.01 | 0.08 | 0.04 | 0.7 | 0.1 | 0.03 | 0.005 | 0.005 |

| TiC | ≥19.1 | ≤0.30 | 0.01 | 0.05 | 0.02 | 0.5 | 0.2 | 0.01 | 0.005 | 0.01 |

| Mo2C | ≥5.85 | ≤0.20 | 0.01 | 0.05 | 0.05 | 0.50 | 0.10 | 0.01 | 0.005 | 0.01 |

| Particle size:0.5-500micron ,5-400mesh |

| Particle size and chemical composition are modified on request. |

Description of Tourmaline heating cloth fabric modifier Zirconium carbide hot cathode material raw materialszirconium carbide powder used for Composite polyurethane insulation materials catalyst

The product basic situation introduced:

Molecular weight:103.22 Carbon content:11.64%

Density:6.73g/cm3 Melting point:3540ºC

Boiling point: 5100ºC

Zirconium carbide is gray metallic powder with cubic system structure of NaCl type.The carbide is chemical stable and has excellent high-temperature property.The mixture of TaC and ZrC(with the mole ratio 4:1)is a thermionic emission having very high melting point.The fine ZrC powder is an important cermet material,which can make cutting tool,incandescent flame,and pyroconductor,et.

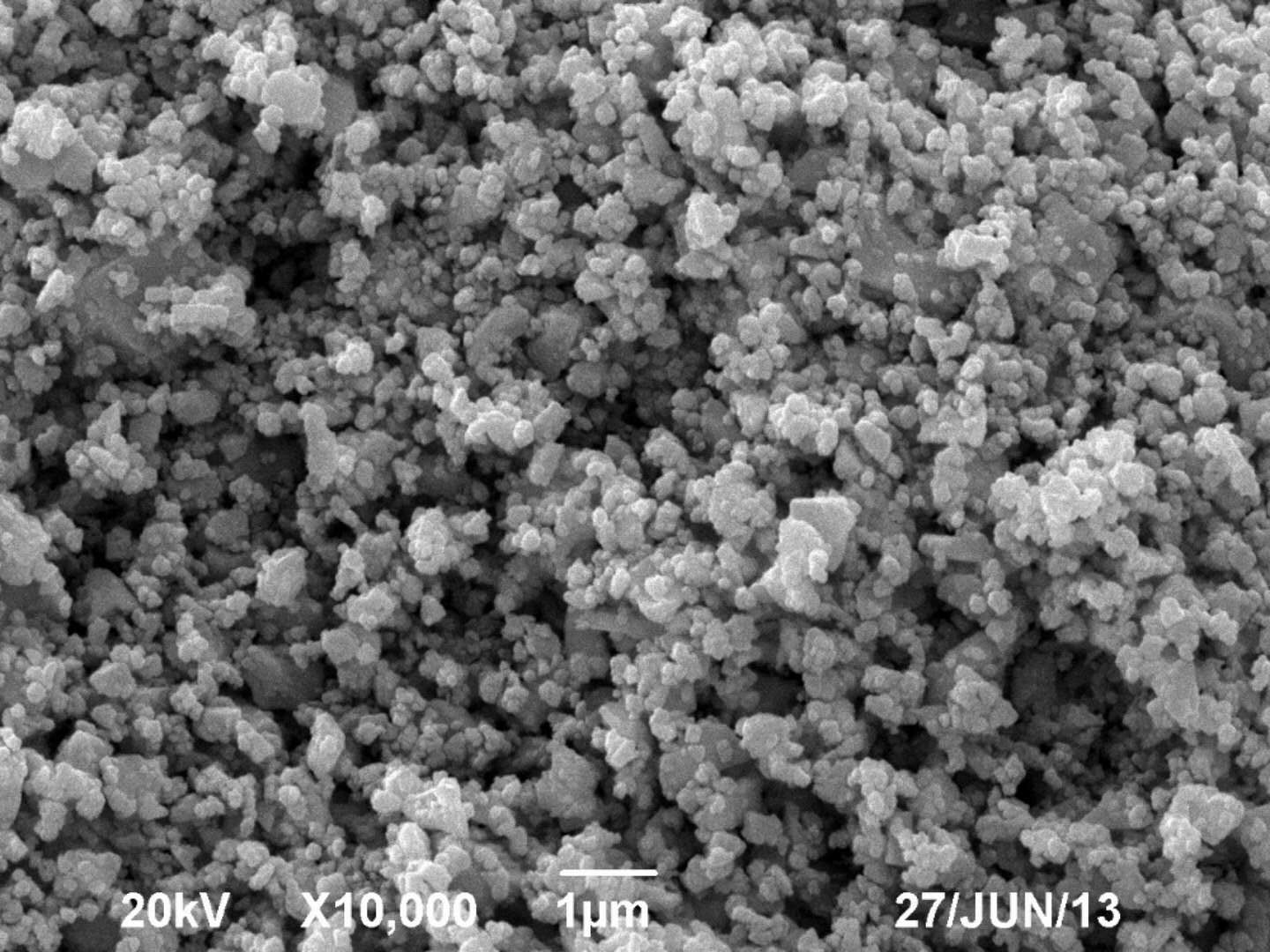

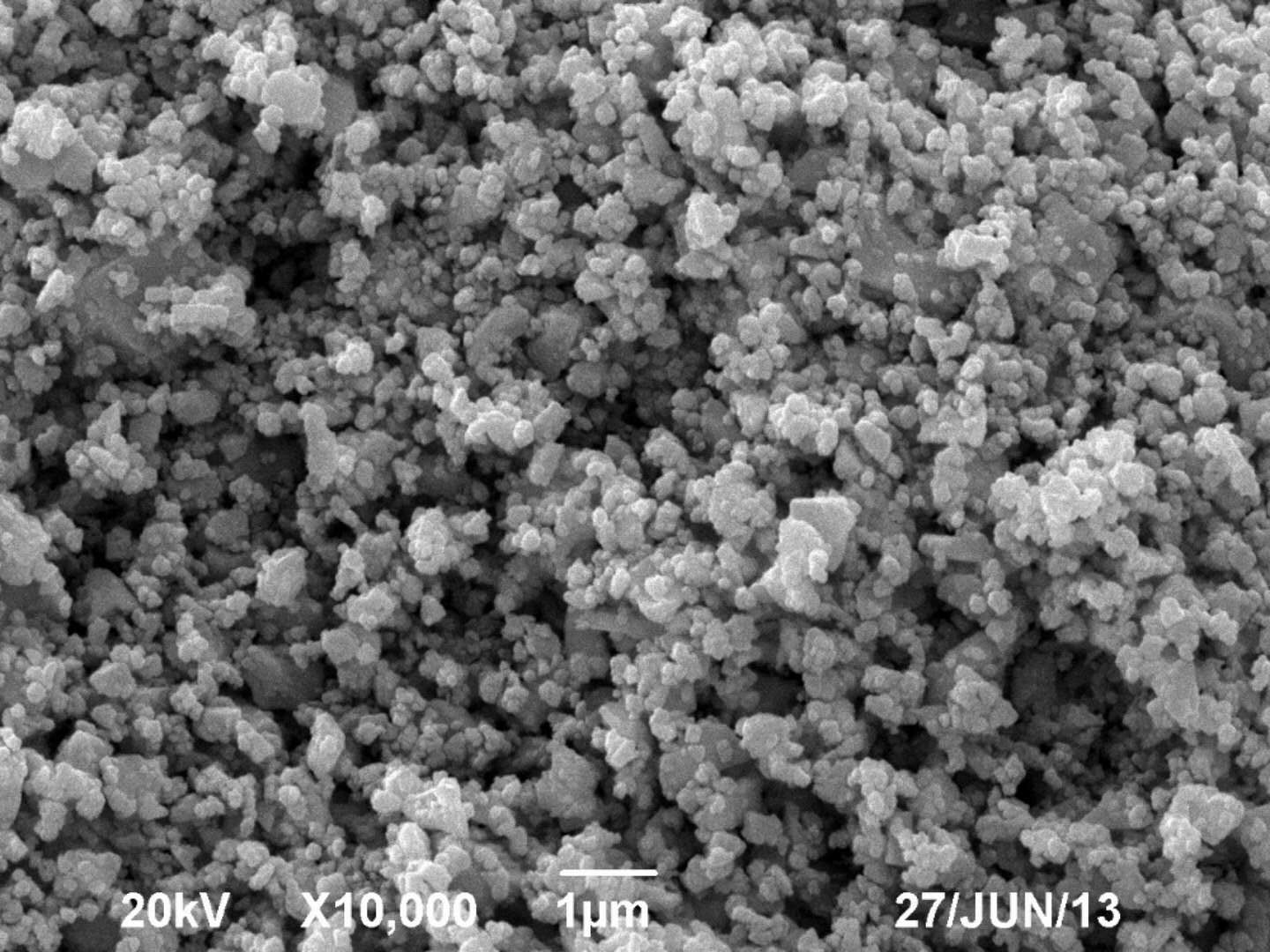

Gray metal powder, is one new material which produces through the new craft, Purity high, the grain-size distribution is even, high surface activity, has thermostability, Oxidation resistance, intensity high, degree of hardness high, the thermal conductivity is good, toughness is good, Is one kind of important high MP, high strength and anti-corrosive high temperature structural material, and has the highly effective absorption visible light, reflection infrared and stored energy regeneration and so on characteristic.

Application of Tourmaline heating cloth fabric modifier Zirconium carbide hot cathode material raw materials:

zirconium carbide powder used for Composite polyurethane insulation materials catalyst

Zirconium carbide cermet powder is manufacture high technology and new technology domain and so on high performance hard alloy,aerospace,atomic energy, textile,electronic,coating,flinty thin film and metallurgy automation key materials.

Zirconium carbide cermet powder is manufacture high technology and new technology domain and so on high performance hard alloy,aerospace,atomic energy, textile,electronic,coating,flinty thin film and metallurgy automation key materials.

1.Zirconium carbide to have the highly effective absorption visible light, reflection infrared and the stored energy regeneration and so on characteristic, applies in the textile profession new heat preservation temperature adjustment textile, the far infrared heat preservation lining, may achieve the heat preservation regeneration, against ultraviolet ray, the radiation protection, antibacterial, the comfortable effect. Suits the manufacture to maintain warmth the underwear, the winter gym suit, the male and female clothing lining, to protect radiation against ultraviolet ray special protection clothing, as well as the swimming jacket and so on new product.

2.Because zirconium carbide to be possible to give off heat automatically, applies the primal chaos to steam the lung vest, realizes coughs the asthma and heart disease's thorough effective treatment.

3.Zirconium carbide to apply in the carbon fiber, enhances the carbon fiber product large scale the wear-resisting performance, the anti-fatigue, the thermostable performance and the intensity, has succeeded applies in the defense industry. Zirconium carbide to apply in the new carbon carbon complex function material, may obviously enhance the compound materials to bear the ablative performance, enhances the heat-resisting rank, is presently widespread the application military, astronautics domain.

4.Zirconium carbide powder body in the anti-infrared reconnaissance application: The nanometer carbonizes not only the zirconium powder body the absorption wave length is smaller than 2μm the high energy beam, moreover the reflection wave length is bigger than 2μm feeble-minded beam. The human body launches heat energy wave length in 10μm about, thus the human body put on has been joining the nanometer to carbonize the zirconium powder body's textile fiber clothing, might prevent the human body quantity of heat radiation effectively, thus avoided by the infrared reconnaissance gear discovering, already succeeded applies in the war industry domain.

5.Zirconium carbide cermet powder to be possible to serve as the electrode, the fireproof crucible and the negative pole electron emission material. As a result of its high degree of hardness, carbonizes the zirconium cermet to be possible to take the grinding compound, uses in each kind of rigid metal, the corundum or the glass processing; May also make takes wear-resisting, the anti-corrosive carbonized zirconium crucible and the cutting tool, but may also use in the nuclear fuel profession, on the electronic installation, tool's wear-resisting protective film, the ultra hard membranous material as well as the high luminance electron emission membrane. The low density carbonizes the zirconium coating heat-resistance stress and the insulating ability loosely is good, may serve as the insulation material; The high density carbonizes the zirconium coating impermeability to be able compactly to be good, may serve as protection coating.

May apply in the coating, does for the thermostable coating, enhances the material the superficial performance.

6.Zirconium carbide is the fire-proof material chemical additive, is produces the atomic energy level sponge zirconium raw material, because its strength at high temperatures and degree of hardness are high, the thermal absorption section is small, the radiation resistance can be good, is taken the gable nuclear fuel pellet barrier the new material. Carbonizes the zirconium to belong to the ultra hard material, the chemical stability is good, has good thermostable, anti-corrosive, the wear-resisting performance, is the good high temperature structural material, the ultra hard tool material and the surface protection material. Simultaneously also has the fine thermal conductivity, in directions and so on cutting tool material, armoring material, built-up welding wear-resisting welding rod has the latent application value.

7.Zirconium carbide also to have the very big development opportunities in the hard alloy, may enhance the hard alloy the intensity, the inoxidizability. uses in astronautics material. ZrC made copper the dissemination to strengthen enhanced the copper mechanical property, applied in integrated circuit's lead frame, each kind of spot welding, seam welder's electrode, the contact material, the armature, power tool's phase changer and so on.zirconium carbide powder used for Composite polyurethane insulation materials catalyst

Tourmaline heating cloth fabric modifier Zirconium carbide hot cathode material raw materials production patent:

Tourmaline heating cloth fabric modifier Zirconium carbide hot cathode material raw materials Packing:

Tourmaline heating cloth fabric modifier Zirconium carbide hot cathode material raw materials Packing:

Why Langfeng Metallic's carbide powder is better ?

Why Langfeng Metallic's carbide powder is better ?1: use high purity raw material : zirconium oxide ZrO2 , carbon black powder. Strictly control in raw material ensure the high purity of end product: zirconium carbide power.

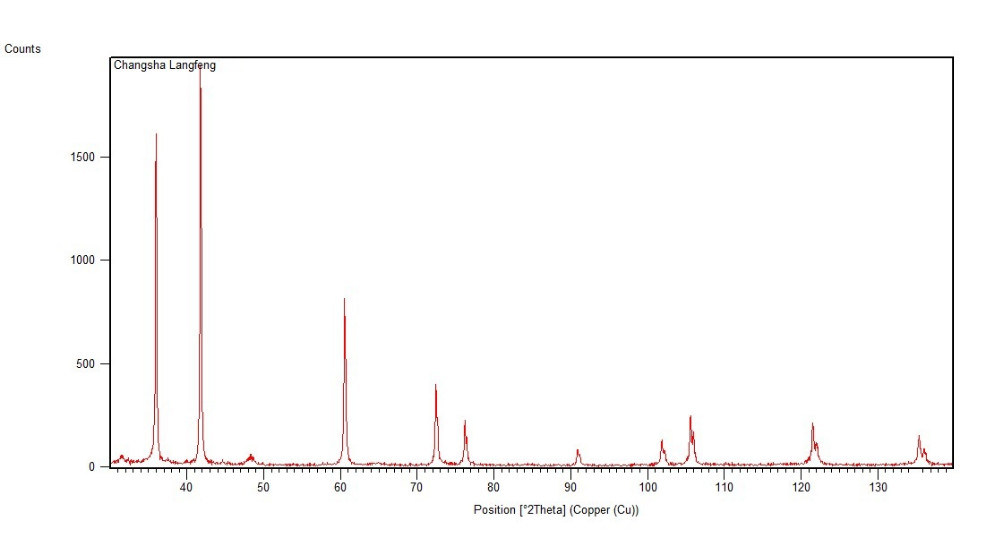

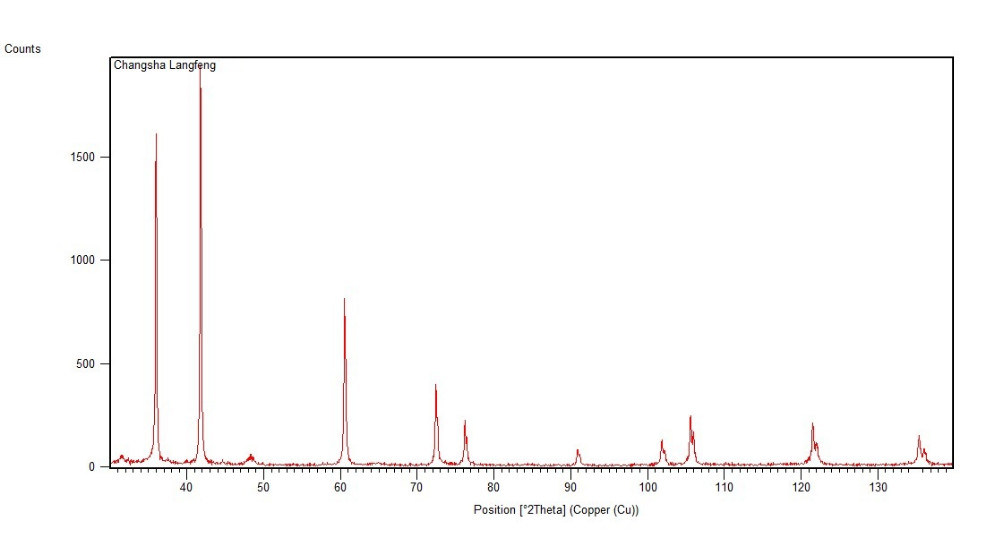

2: good grain-size distribution, contact us for SEM photo and PSD (particle size distribution) report ;

3: unique technology in additive process;

4: unique sintering process ensure low oxygen and free carbon content , which bring high quality product;

zirconium carbide powder used for Composite polyurethane insulation materials catalyst

FAQ:1. Can I negotiate the Prices? Yes, we may consider discounts for bulk orders of individual products. 2. What is your minimum order requirement? We will indicate the MOQ for each item in the quotation sheet.We accept the sample and trial order. If the quantity of single item can't reach the MOQ, the price should be sample price. 3. How long will it take to execute my order? For the stock items, we can arrange the shipment within 3days after received your payment. For the customized items, we will indicate the delivery time in the quotation sheet. 4. Can you give warranty of your products? Yes, we extend a 100% satisfaction guarantee on all items. Please feel free to feedback immediately if you are not pleased with TDOER 's quality or service. Our factory major products as following:

Changsha Langfeng is a metallic material factory,we specialized in carbide powder for 10 years,with the customers of Germany,Korea,USA,Canada etc.Specially zirconium carbide powder is our patent product:1) High purity Metal Carbide powder,such as ZrC powder,HfC powder,VC powder,Cr3C2 powder,Mo2C powder,NbC powder,TaC powder,Compound carbide powder,such as(Ta,Nb)C powder,Ti(C,N)powder,(W,Ti)C,(W,Ta)C,(Ti,Ta)C,(W,Ti,Ta)C,(W,Ti,Ta,Nb)C powder,etc.(Key raw materials of: thermal spray,plasma coating,semiconductor,3d printing,abrasives, carbide cutting tools,cermet products, welding materials, military industry, aerospace industry,etc.)

2) TiC cermet rod / TM52/60 of Steel based cemented Carbide rod as Wear-resistant alloy hammer material

3) Carbide rod & Cermet rods. (very suitable finish machining, for some CNC cutting tools)

4),Carbide tile/glass cutting wheels (for cutting a variety of ceramic tile and glass,long service life)

Some FREE SAMPLES can be sent if you need for testing.Contact with me,let's talk details!

Will you want a try? I will always do my best to support you!

Linkedin: https://cn.linkedin.com/in/carbidepowdersuppliers;

Facebook: https://www.facebook.com/carbidepowder;

Changsha Langfeng Metallic Material Co., Ltd, founded in 2009 Changsha Long-ping High-Tech Park, is an patent-owning firm specializing in metal carbide powders' research, production and sale.

With 100 sets of various manufacturing equipments covering the process of raw material mixing, carbonization, sintering, grinding, sieving, mixing and packing, the group distinguishes itself also by 182 workers and 2 academician in engineering material from Chinese Academy of Science. Furthermore, we established technical support relationship with Powder Metallurgy Research Institute of Central Sounth University and Changsha Research Institute of Mining And Metallurgy.

Our products: Metal carbide powder, multiple carbide powder, compound powder, Ti(C, N) Based cermet, Tungsten carbide tile cutter, glass cutter wheel, planetary ball mill, industrial microwave furnace.

Our goal:

In the next five years, we face the task of expanding investment of US$80 million. In 2023, a new R&D base for new materials will be established, and sales revenue goal is US$10 billion.

Company culture:

Vision: Driving force in technical progress

A world leader in the field of new materials

Mission: Create value for the whole world

Operation idea: Good faith, high quality, innovation, win-win

Serve concept: Warm, excellent, quick and considerate services.

Spirit: Never give up, Never stop

Team work, make dream come true;

Value: Quality win honor, service win reputation;

Responsibility: Create value for customers, set up developing stage for staff.

We guaranteed products at a competitive price and high quality. At present, our products have a very good sale in domestic and overseas market. We wish to cooperate with you to create a bright future and mutual benefit. Much appreciation for your prompt attention in advance, we are eager to look forward to hearing from you soon.