hollow plastic production making machine/blow moulding machine :extrusion blow molding machine is an assemble machine ,including extruding and parison die head , blow up system ,clamping system ,parison controller system and transmission system. Blow molding (blow moulding machine ), also called hollow blow molding, is a rapidly developing plastic processing method. The tube shaped plastic billet obtained by extrusion or injection molding is heated (or heated to softening state) and is placed in the open die. The compressed air is put into the air immediately after the mould is closed, so that the plastic billet is swollen and pressed on the inner wall of the mold. After cooling off the mould, all kinds of hollow products are produced by this kind of processing way .

blow molding machine main parts :

blow molding machine main parts :1. MITSUBISHI Japan PLC +WINVIEW Touch screen, making the operation easy. Automatic malfunction alarm with selfdiagnosis, making the malfunction clear at a glance.

2. Center input die head, eliminating the kint line completely and making it easy to change the material and color.

3. Double liner rolling moting guider in moving, opening and closing mold, making the claming force equally distributed, so the cut is smoother.

4. Control the hydraulic system with imported proportional valve YUKEN Japan, ensuring the action steasy, accurate and energy saving 35%.

5. High speed and efficient plasticizing system, mixing well and ensuring the produce purity

6. Clamping system: Diagonial two die bar center clamping bi-directional high precision linear guide lamping device.

blow moulding machine parameter :

MACHINE MODEL |

|

HZB120Zz |

max container capacity |

L |

500 |

machine dimension |

M |

9.1*3.6*5.6 |

total weight |

ton |

45 |

|

|

|

clamping force |

kn |

1500 |

platen opoening stroke |

mm |

600-1400 |

platen size |

mm |

1400*1750 |

max mould size |

mm |

1110*2000 |

minimum mould thickness |

mm |

610-750 |

|

|

|

motor power of pump |

kw |

127.5 |

air pressure |

mpa |

0.18*6 |

air consumption |

m3/min |

1 |

total power |

kw |

1 |

average engergy consumption |

kw |

152 |

|

|

82 |

screw diameter |

mm |

120 |

screw L/D ratio |

|

24 |

plasticing capacity |

kg/hr |

280 |

number of heating zone |

|

6 |

extruder heating power |

kw |

32 |

extruder driving |

kw |

90 |

|

|

|

number of heating zone |

|

6 |

power of die head |

kw |

39 |

max die pin diameter |

mm |

500 |

max die capacity |

L |

25-70 |

|

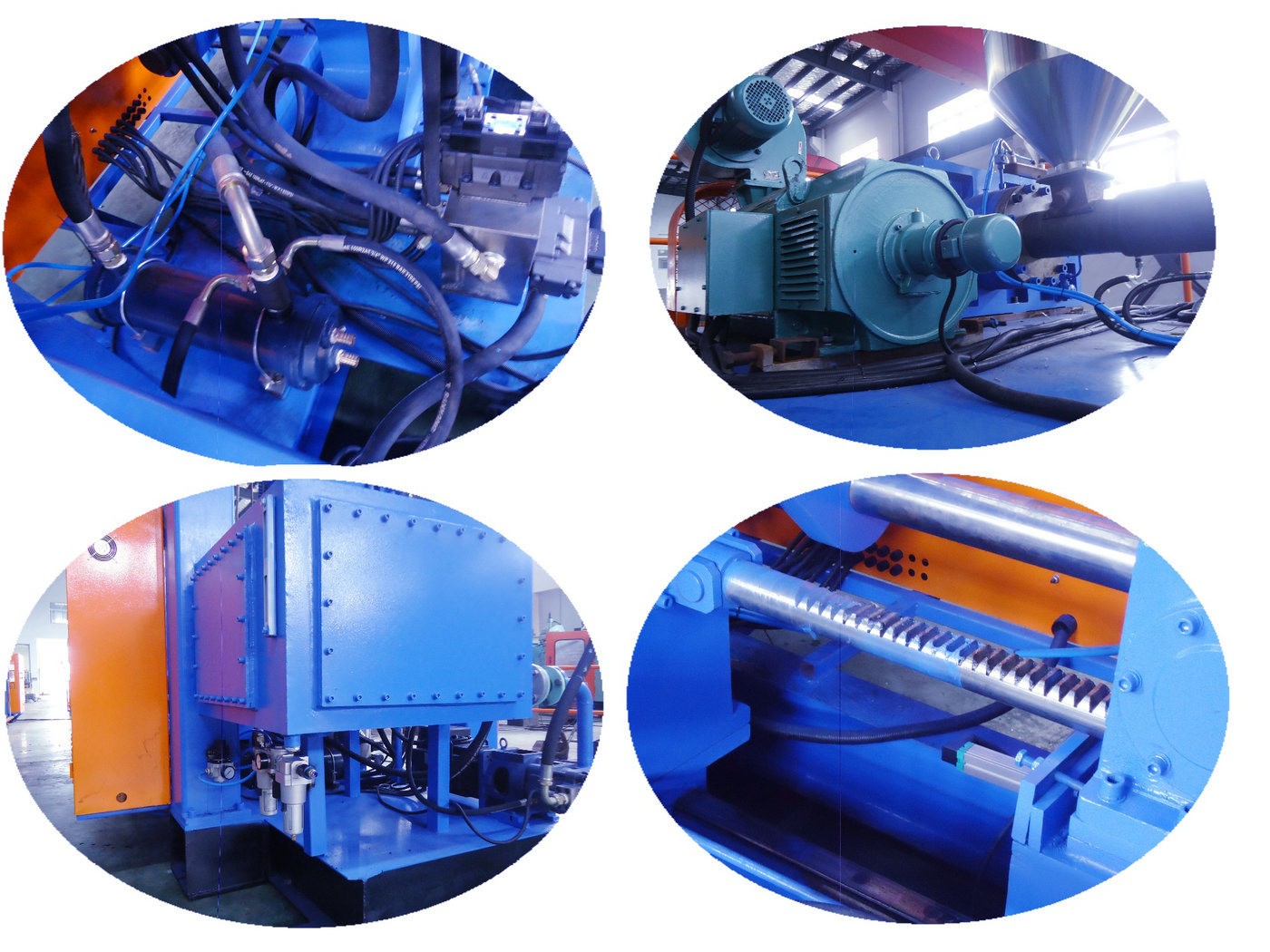

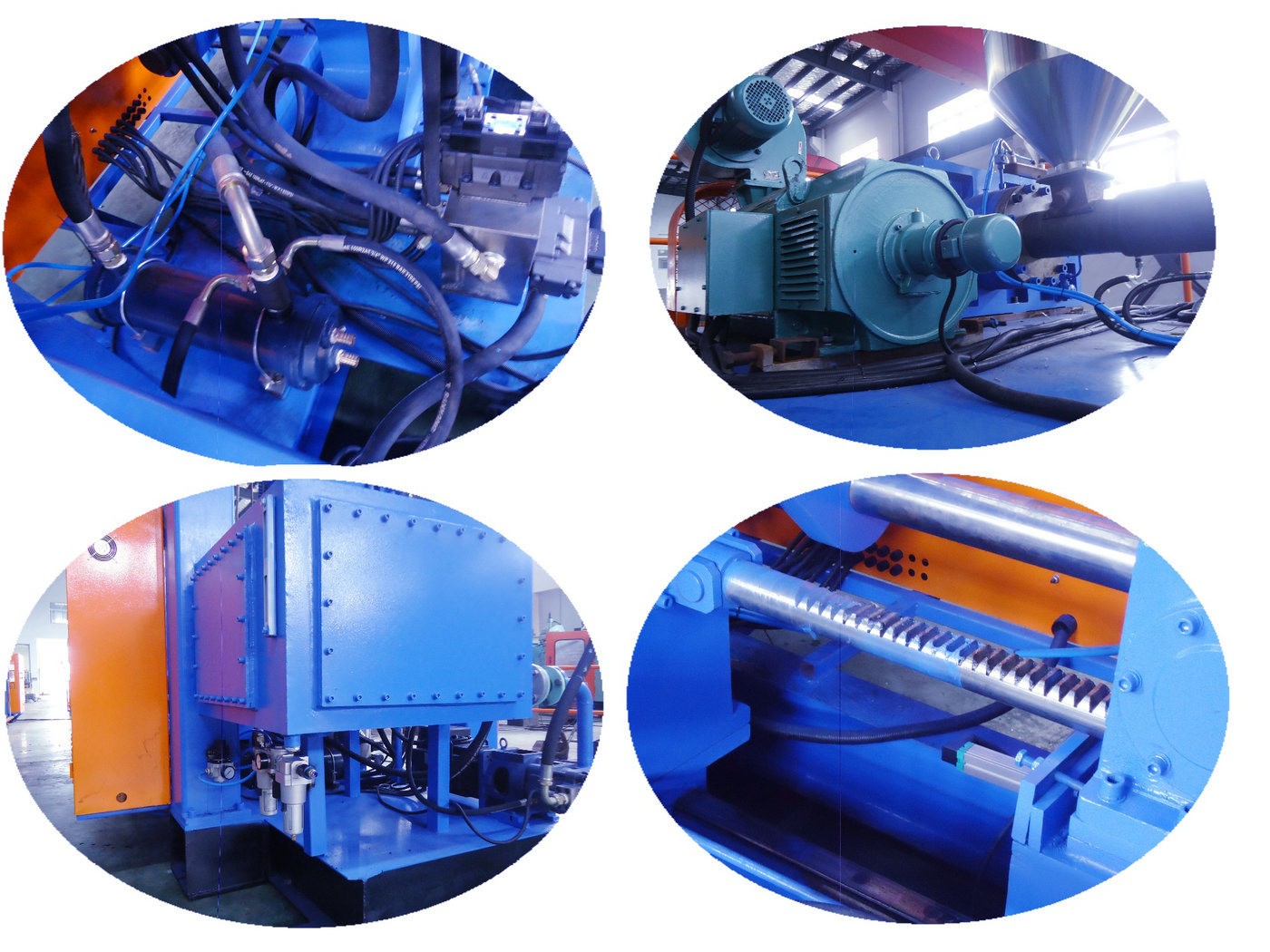

blow molding machine parts photos : hydraulic parts and oil tank , extruding system and so on . package for blow molding machine :

hydraulic parts and oil tank , extruding system and so on . package for blow molding machine : | machine parts name | brand |

| PLC | mitsubishi |

| thickness controller | MOOG |

| hydraulic valve | yuken |

| oil pump | rexroth germany |

| inverter | emerson usa |

for shipping blow molding machine and auxiliary machines , mould , we adopt wooden box ,wooden pallet for packing them .

if customer's have different requirement about blow moulding machine , we will think of it ,welcome to talk with us !

Helen dongZhangjiagang Haozhao machinery Co., Ltd

Add: LuyuanJuqiao Development, Tangqiao Town, Zhangjiagang City, Jiangsu Province, China

Mobile: 0086-158-9559-1011.Web: http://www.haozhaojx.com

Zhangjiagang haozhao machinery Co., Ltd is located in zhangjiagang city, which is famous for its pretty scenery and convenient land-and-water transportation, lies to the north of the Shanghai, nanjing highway, to the west of Shanghai, to the south of nantong, embracing predominant position, mature economic environment and convenient communication.

The company owns more than 30, 000 square meter international standard workshop and more than 300 excellent staffs. Importing the newest Japanese technology, and form a powerful R&D team, which consist of many experts, engineers and technical man, to guarantee the quality.

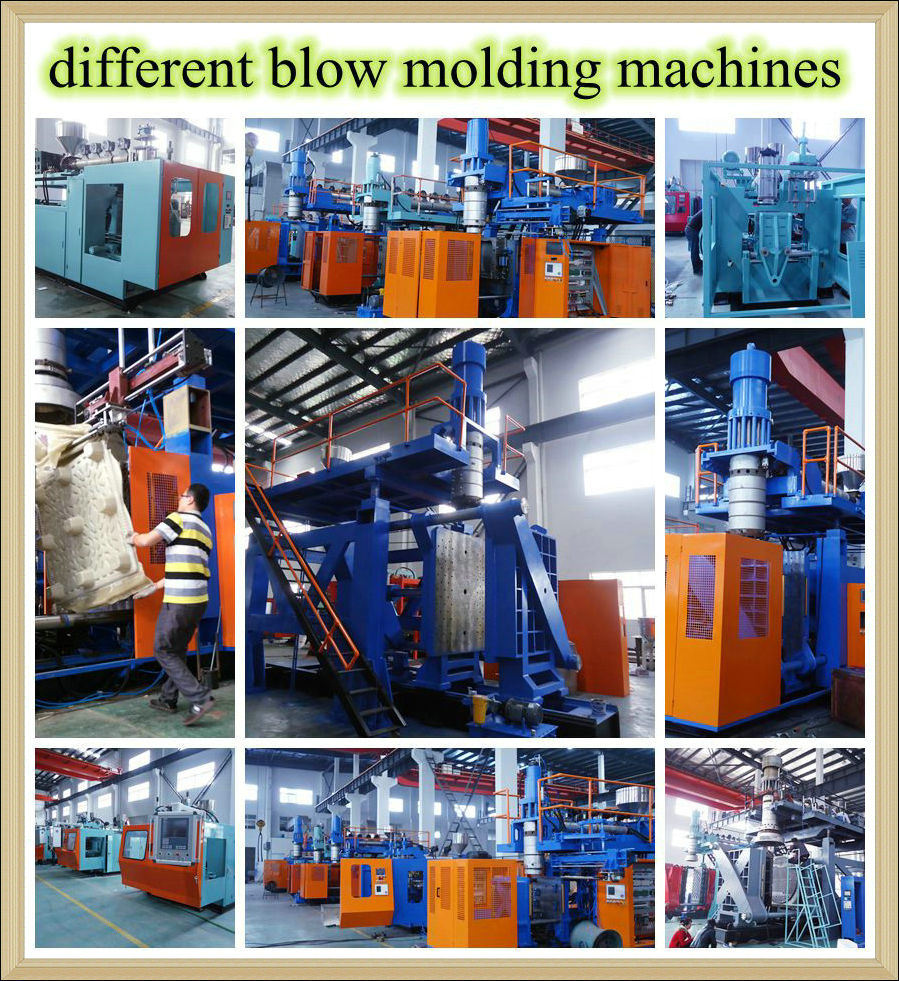

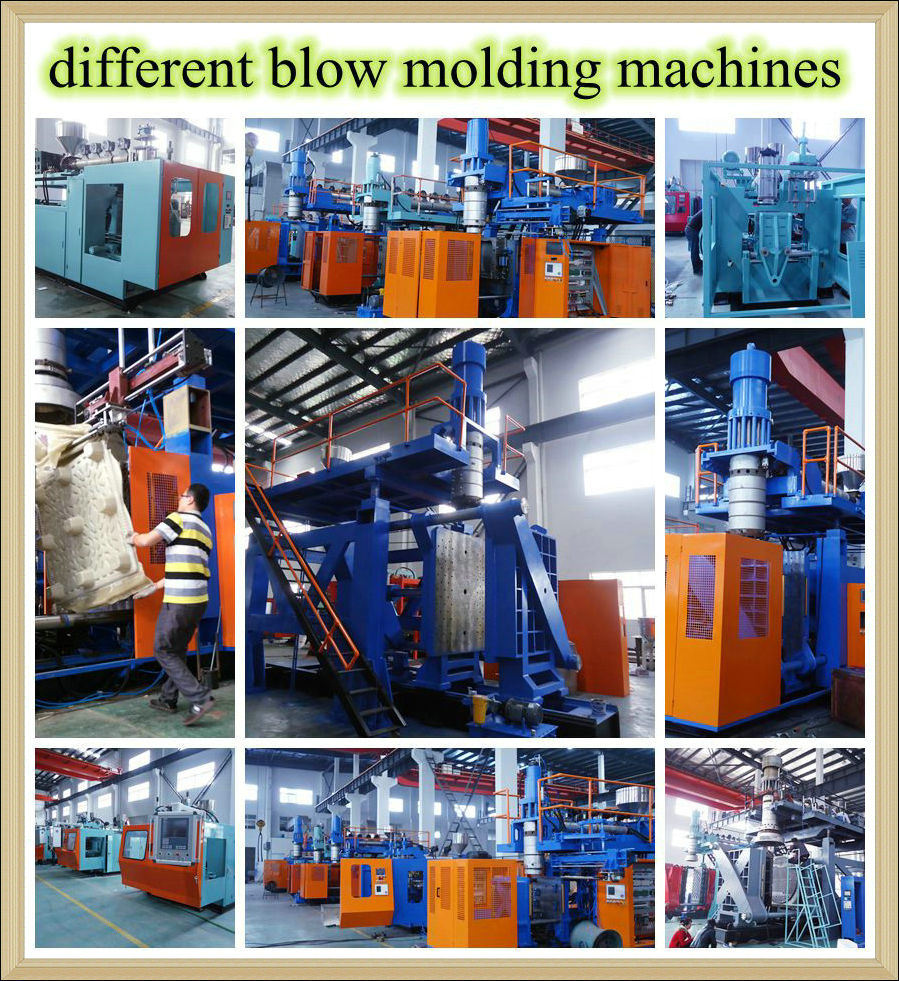

We are professional in the field of blow molding machines, our product line covers wide range, including more than 100 types of automatic blow molding machines, for the products from 5ml to1000L, such as bottles, drums, jerry cans, kettles, boxes, auto-parts, chairs, oil tanks, pallets and other plastic hollow products. According to customer's requirement, we supply single die head, double die head, triple die head, four die head, single layer, double layer. Triple layer, quadruple layer, sextuple layer and so on.

We can help our customers to solve different problem and supply related machines suitable for different materials, such as PE, PP, PVC, PA, PS, ABS, EVA, PETG, EVOH… .

Our philosophy: Research & development is the soul, quality is the life, marketing demand is the goal!

Our management policy: Excellent and high-efficient products, top-ranking services!