Bottle Blow Molding Machine for PE Shampoo Bottles

| Price: |

US $ 30000-50000/Piece |

| Min Order: |

1/Piece |

| Pay Type: |

L/C,T/T,D/P |

plastic bottle/jerry can blow moulding machine :

plastic material -blow molding machine extruding system - machine rdie head - extruding material -- bottle mould - finished bottle - conveyor into leak test machine - packing box

deflash material into crusher machine for recycle material .

it can choose different number of die head for extrusion blow moulding machine according to the volume of production, there are four sizes of die head :single die head , double die head , triple die headd , four die head ; if volume of bottle is less than 1000ml , triple die head is better choice . double die head is better for 1000ml-2000ml , single die head is for 2500ml-5000ml .human machine interface and color touch screen ,precison parison controller system are used on the blow molding machine ,the die head allows feeding from the side , from center,with double bagand through screw feed and so on .automatic deflash device are installed on the machines ,wchich are optional .

blow molding machine parameter :| | | HZB70D |

| material | | |

| max container capacity | L | 5 |

| number of die | set | 1.2.3.4 |

| ouput dry cycle | pc/hr | 1000 |

| machine dimension | m | 3.3*2.3*2.6 |

| total weight | ton | 5.8 |

| | | |

| clamping force | kn | 68 |

| platen opening stroke | mm | 200-500 |

| platen size | mm | 330*370 |

| move mould stroke | mm | 420 |

| mould thickness | mm | 205 |

| | | |

| motor power of oil pump | kw | 15 |

| max pressure | mpa | 12 |

| air pressure | mpa | 0.7 |

| air consumption | m3/min | 0.6 |

| average energy consumption | kw | 23 |

| | | |

| screw diameter | mm | 70 |

| screw L/D ratio | L/D | 24 |

| plasticizing capacity | kg/hr | 70-80 |

| number of heating zone | zone | 3 |

| extruder heating power | kw | 14.2 |

| extruder driving power | kw | 22 |

| | | |

| number of heating zone | zone | 3 |

| power of die heating | kw | 5.7 |

| max die pin diameter | mm | 135 |

| center distance of double die | mm | 160 |

| center distance of tri-die | mm | 110 |

| center distance of tetra-die | mm | 85 |

main parts for blow moulding machine :| touch screen | winview taiwan |

| PLC | mitsubishi Japan |

| contactor | Schneider |

| motor | mengniu |

| servo system | MOOG japan |

| hydraulic valve | YUKEN |

| pneumatic valve | Festo GERMANY |

| transducer | Emerson USA |

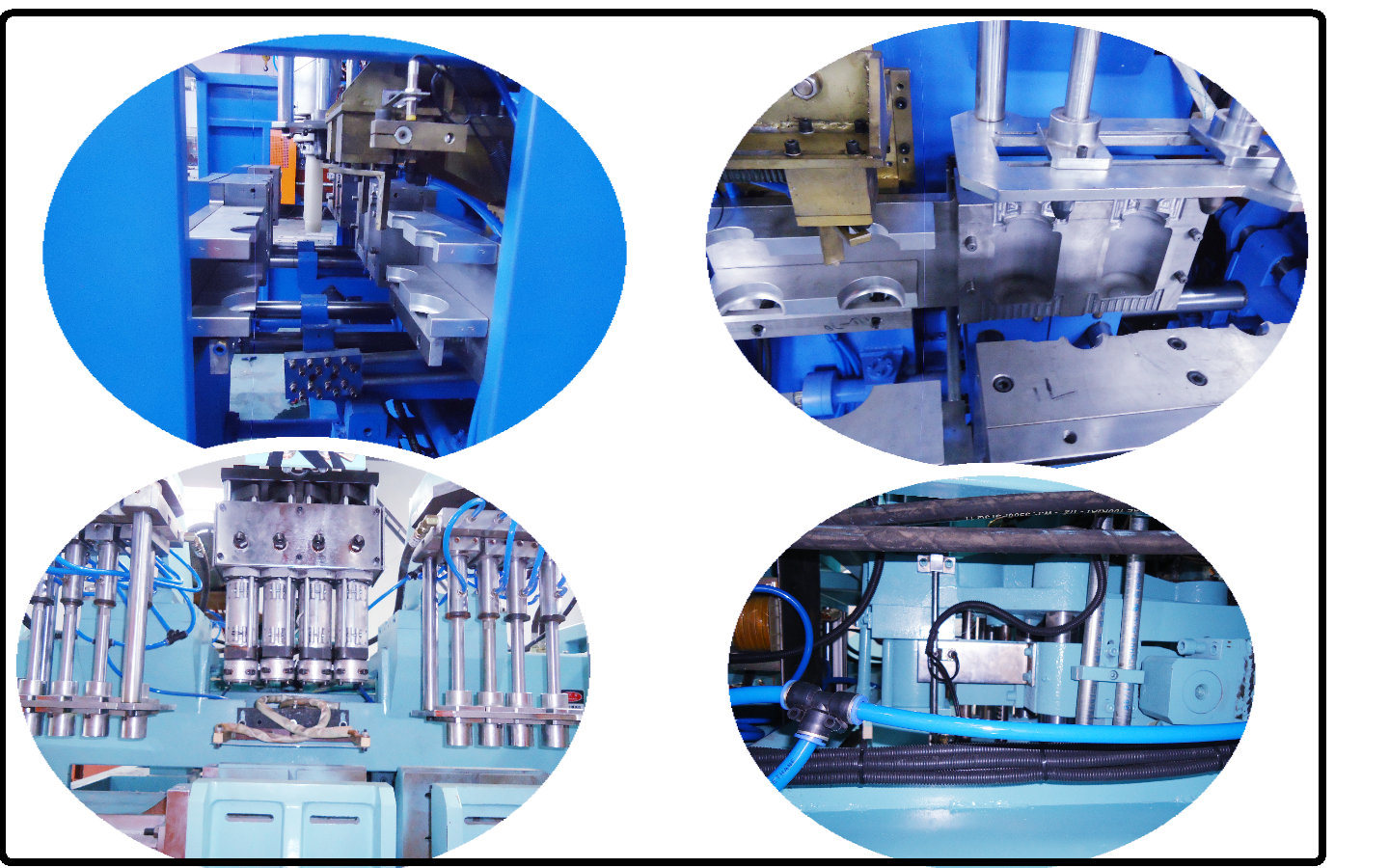

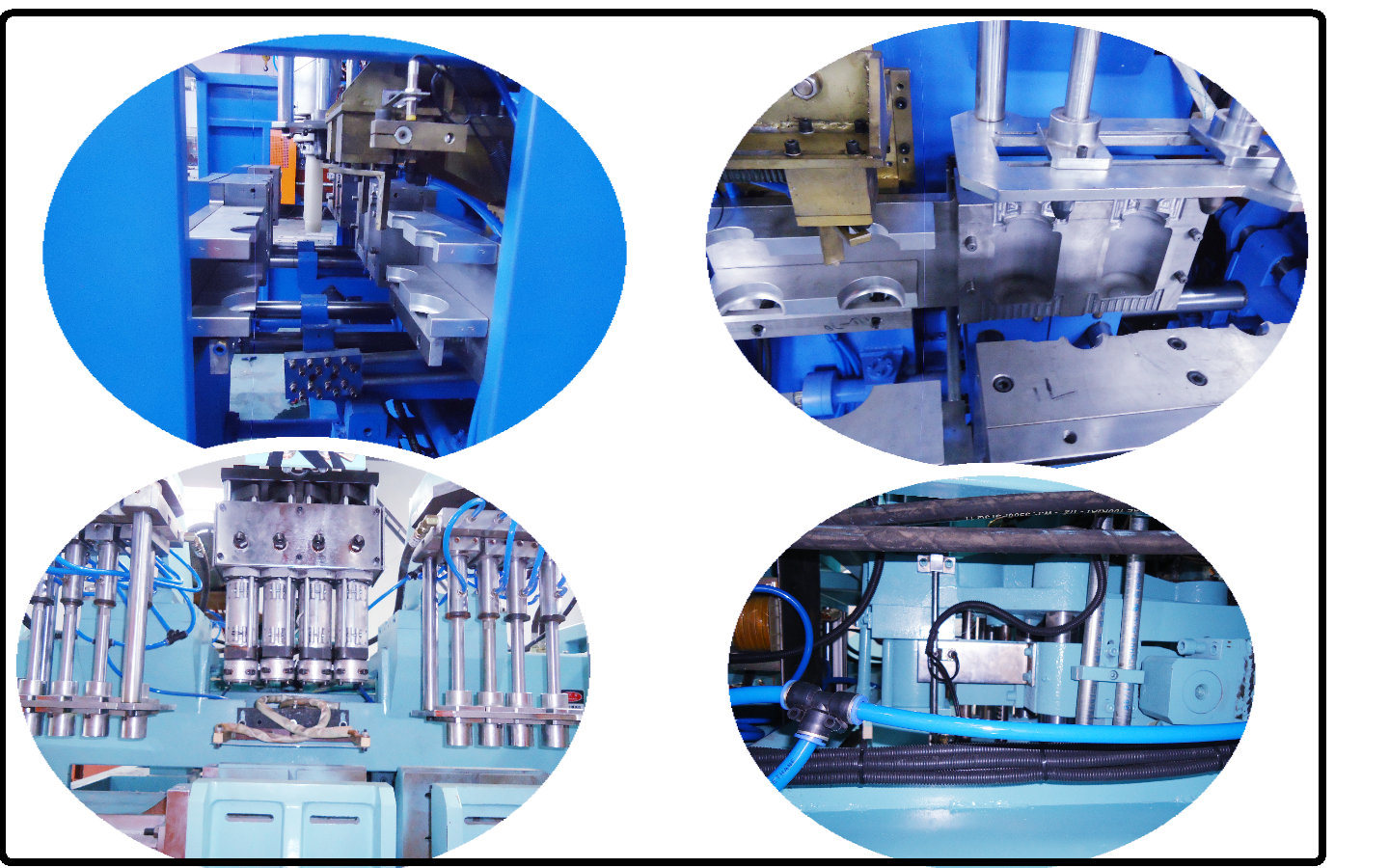

1.blow molding machine -clamping system -double tie bar clamping system and high precision linear guide rail moving mould platen device

2. hard gear bo and import inveter

3. control-incoming die with special vontrol

4. hydraulic valve ,seal parts proprorional control

5. import PLC and and human -machine touch screen

package for ship blow moulding machine:

package for ship blow moulding machine:

wooden box for packing mould and machine parts , film and wooden pallet for packing blow molding machine.

auxiliary machines are match with blow molding machine

auto loader :loading plastic material in to blow molding machine hopper;Vacuum feeding machine is a modern chemical, pharmaceutical, food, metallurgy, building materials, agricultural and other industries must be one of the light and heavy equipment, it provides transportation efficiency, accurate, durable and reliable quality, and in the process of feeding raw materials not damp, not to be polluted, with no foreign body no, leakage, self transport and realize the feeding process, to avoid the risk of aerial feeding, reduce labor intensity, improve production efficiency.crusher machine : Plastic crusher, also known as plastic grinder, is mainly used to crush all kinds of plastic and rubber, such as plastic profiles, pipes, rods, threads, films, and used rubber products.

The granular material can be used directly for the extruder or injection molding, and can also be regenerated by the basic granulation. The plastic crusher is also a peripheral equipment of the injection molding machine and blow molding machine, which can break recovering the defective products and the water mouth of the injection molding machine/blow molding machine .

air compressor :It is the gas source power, the core equipment of the pneumatic system.

chiller :Inject water -water tanker -chiller machine cooling water -pump water into -blow molding machine - recycle water into water tanker .mixer machine :The color mixer uses the whirlpool of the dialing blade for high speed operation.

Plastic particles (or resin powder) high speed rolling collision and friction heat,

A machine that makes the material vaporize rapidly from the exhaust pipe to the purpose of drying at the same time as the material is mixed. Contact person :Helen dong sales managerZhangjiagang Haozhao machinery Co., Ltd Add: LuyuanJuqiao Development, Tangqiao Town, Zhangjiagang City, Jiangsu Province, ChinaMobile 0086-158-9559-1011. Web: http://www.haozhaojx.com

Contact person :Helen dong sales managerZhangjiagang Haozhao machinery Co., Ltd Add: LuyuanJuqiao Development, Tangqiao Town, Zhangjiagang City, Jiangsu Province, ChinaMobile 0086-158-9559-1011. Web: http://www.haozhaojx.com

| Prod Model: |

70D |

| Capacity: |

2000-5000ml |

| Material: |

HDPE, PP, PE, PVC |

| Motor: |

Mengniu |

| Air Switch: |

Festo |

| Hydraulic Valve: |

Yuken |

| Barrel &Screw: |

38crmoala |

| Thickness Controller: |

Moog Japan |

| Touch Screen: |

Winview Taiwan |

| Deflash System: |

Optional |

| Gear Box: |

Guomao |

| Type: |

Extrusion Blow Molding Machine |

| Raw Material: |

HDPE |

| Making Method Of Parison: |

Extrusion-Blow Molding |

| Automation: |

Automatic |

| Computerized: |

Computerized |

| Certification: |

CE |

Zhangjiagang haozhao machinery Co., Ltd is located in zhangjiagang city, which is famous for its pretty scenery and convenient land-and-water transportation, lies to the north of the Shanghai, nanjing highway, to the west of Shanghai, to the south of nantong, embracing predominant position, mature economic environment and convenient communication.

The company owns more than 30, 000 square meter international standard workshop and more than 300 excellent staffs. Importing the newest Japanese technology, and form a powerful R&D team, which consist of many experts, engineers and technical man, to guarantee the quality.

We are professional in the field of blow molding machines, our product line covers wide range, including more than 100 types of automatic blow molding machines, for the products from 5ml to1000L, such as bottles, drums, jerry cans, kettles, boxes, auto-parts, chairs, oil tanks, pallets and other plastic hollow products. According to customer's requirement, we supply single die head, double die head, triple die head, four die head, single layer, double layer. Triple layer, quadruple layer, sextuple layer and so on.

We can help our customers to solve different problem and supply related machines suitable for different materials, such as PE, PP, PVC, PA, PS, ABS, EVA, PETG, EVOH… .

Our philosophy: Research & development is the soul, quality is the life, marketing demand is the goal!

Our management policy: Excellent and high-efficient products, top-ranking services!