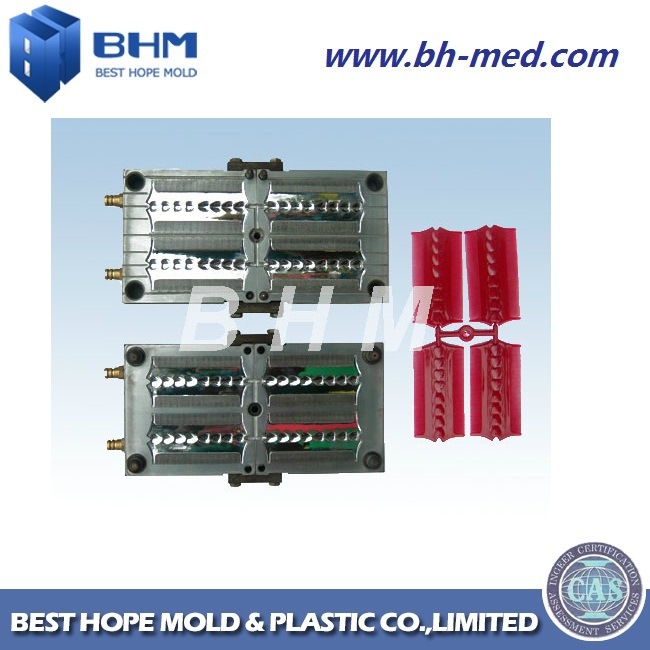

Plastic Mould for Dental Plastic Parts

Our tool factory are able to build moulds ranging from small to large size; From single cavity and prototype molds to multi cavity and family molds.

BHM is engaged in moulds design and tooling for all kinds of precision moulds for healthcare products at competitive price.

We supply mould making and plastic injection work for the Dental plastic parts with different custom design and size.

Moulds Constructions:

Cavity No.: According to customer's quantity or injection machine size

Runner type: Cold Runner (hot runner also available)

Core and Cavity Material: S136 / NAK80/ H13 etc. As per customer request

Mold Life: 1 million shots or more

Lead Time: 35-40 days

At the same time BHM provides plastic injection molds maintenance services and necessary free mold spare parts are offered along with mold. With our advanced equipment and rich experience we are ready to meet your unique tooling requirements with high quality and competitive cost.

Looking forward to your enquiry!

| Company Name | Best Hope Mold & Plastic Co., Ltd |

| Part Material | ABS, PC, PP, PE, Nylon, POM, TPU, TPE, PVC, PTFE, PVDF^ |

| Engineering | CAD, UG, ProE, CAD, Solidworks, Mastercam, Cimatron^ |

| Mold Grade | SPI CALSS 101 MOLD, SPI CLASS 102 MOLD |

| Cycles/Mold Life | One million or more, under 500, 000 ^ |

| Mold Base | LKM, DME, Hasco^ |

| Mold Spare Parts | DME, HASCO, MISUMI, LKM ^standard |

| Mold Type | Cold runner, hot runner, hot to cold runner, automatic mold, insert mold, over mold, twin-shot mold ^ |

| Hot Runner Brand | Husky, YUDO, Mold Masters, Synventive, Mastip^ |

| Demoulding | Motor, oil cylinder, stripping plate, slides, angel pin, ejector sleeves ^ |

| Equipment | Miller, Gantry Milling, Driller, CNC, high speed CNC, EDM, 2-end, low speed wire cut, CMM, |

| Lead Time | 3-10 weeks according to complexity of mold |

| Packaging | Fumigation-free wooden box |

| Main Markets | Medical, Automotive, Plastic Packing, Electronics, Appliances^ |

Work Flow

(Basic Steps,

We do more than this described) | 1. You send us samples or ready drawings |

| 2. We confirm DFM, final drawings with you |

| 3. We start tooling and update tooling progress to you every week |

| 4. Finish tool and tool trial out |

| 5. Send you tool trial samples by DHL, Fedex, TNT, UPS, Aramex, ^ |

| 6. Until you confirm samples, we inspection mold, pack it for shipping |

Best Hope Mold & Plastic (Shanghai) Co., Ltd (BHM) focus on high precision Plastic Injection Molds design and developing, as well as custom injection molding.

BHM' S Facilities:

BHM owns two facilities located in Shanghai and Suzhou, respectively focuses on high precision molds and large size molds.

Since established in 2005, BHM has been developing very fast, business expands rapidly due to quality products and serves, At present, BHM has covers an area of 10000m2 in total and owns 185 employees including 28 engineers, 110molds makers, 10 QC personnel and many injection operators.

BHM' S Capabilities:

BHM offer one-stop services from engineering design, tooling, to custom injection molding, as well as printing and assembly etc.

Design for manufacturability and efficient production is our primary objective. The mold drawings can be finished within 2-4 days then send to customer for checking before tooling. We are able to meet our customers' Shortened lead time. All the necessary technical drawings will be sent to customers for future mold maintenance references.

Our high speed milling machine, EDM, WEDM and CMM optimize our tooling process and improve accuracy and efficiency of our mold to ensure customers can get quality product.

Our expertise in tooling leads to better results in molding. We have 11 injection machines for mold trial, mold validation and custom production.

We have enough experience working with materials such as: LDPE, HDPE, PP, ABS, PC, PS, PVC, PA, PMMA, POM, TPU, TPR, TPE etc.