Utech 3-in-1 Glass Bottle Wine Making Machine (BCGF Series)specificationsenergy saving glass bottle fruit juice packing equipment

1.3 in1 mono-bloc

2.Material:SS304

3.Application:negetive pressure fillingIntroductiona.The machine incorporates washing,filling and camping into one and it is a kind of full-automatic equipment.

b.It is widely used for alchol ,grape wine ,soy sauce, vinegar and so on.

c.The machine adopts plain cam structure and vacuum-breathing principle,makes filling easy and stable.

d.The machine structure is simple and performance is reliable and is widely used for many types of bottle.

e.Meanwhile it has precise filling level,no bottle break and leakage ,easy operation and maintenance.Feature>>304 Stainless steel construction , and the liquid contact parts are 316L stainless steel

>>All contact parts can be Teflon, Vinton and hoses per your requirements.

No bottle ,no fill, PLC control

The filling blocked nozzles are anti drops, silk, and auto cut viscous liquid

Accurate filling volume, within ±1% and a total bottle counter.

Easy to maintain, no special tools are required.

Special seals or hoses are adapted if the liquid are corrosive.

Diving nozzles for bottom up filling of foaming products if need

Bottle mouth can be located.

Working principle1. high efficient hot filling machine/filler range from 3000bph to 30000bph, can apply to juice, tea, sport drinks, function drinks, etc.

2.Rinser/Filler/Capper Monobloc

Size of bottle: 500ml (300ml-2000ml)round glass bottle twist-off cap

Method of bottle transferring: hold bottle body

Products: Tea/juice/sports drink/milk beverage.

Composition: -Base -Rinser -Filler -Capper Working part details1). Rinser -Rotative rinsing turret one treatment, fixed nozzles, with grippers. -The grippers take the bottles from the inlet starwheel while they are still driven by the starwheel, thus guaranteeing a safe grip. -After the gripping, the bottle is turned upside down and centred above a spraying nozzle which directs a stream of rinse water into the bottle. After the draining period the bottle is turned over to an upright position again.

(2). Filler -The starwheels drive the bottles always "hod bottle body" through the rinsing, filling and capping steps. For the various types of bottle, it is easy to adjust the structure for the operator by our specialized design. -Product bowl is to reduce the loss of heat. -If the temperature is low than the setting value, the filling valves will stop and return the last beverage in filling valve to recycle tank and return to UHT again to sterilize with pump.

(3). Capper - trembling cap unscrambler. Magnetic cap grapping. twist-off capping device.The main picture

The details of the machine(washing ,filling and capping )

Easy operation and technical parts

Easy operation and technical parts1 Using programmable controller to realize fully automatic control from bottles entering to finishing packing.

2 Using transducer as speed regulator, so the user can regulate the machine easily to suit different power requirements.

3 Adopting equal pressure filling principle and current spring valves in order to assure beverage quality.

4 Using advanced magnetic coupler to regulate cap-screwing torque, in order to assure capping quality.

Technical parameter

Model | Washing heads | Filling heads | Capping heads | Capacity(b/h)500ml | Motor power (KW) | Overall dimension(mm) |

BCGF14-12-5 | 14 | 12 | 5 | 2000bph | 1.5KW | 2100x1400x2500 |

BCGF18-18-6 | 18 | 18 | 5 | 3000bph | 2.2KW | 2460x1720x2650 |

BCGF24-24-6 | 24 | 24 | 6 | 4000bph | 3KW | 3100x2100x2650 |

BCGF32-32-10 | 32 | 32 | 10 | 6000bph | 4KW | 3500x2500x2650 |

BCGF40-40-10 | 40 | 40 | 10 | 8000bph | 7.5KW | 4600x1800x2650 |

BCGF48-48-12 | 48 | 48 | 12 | 9000bph | 9.5KW | 5200x4500x3400 |

BCGF60-60-15 | 60 | 60 | 15 | 12000bph | 12KW | 6500x4500x3400 |

wrap the whole body of the machine.In order to make sure the machine new and no rust.

we will give you a new material with complete body and comfortable appearance.

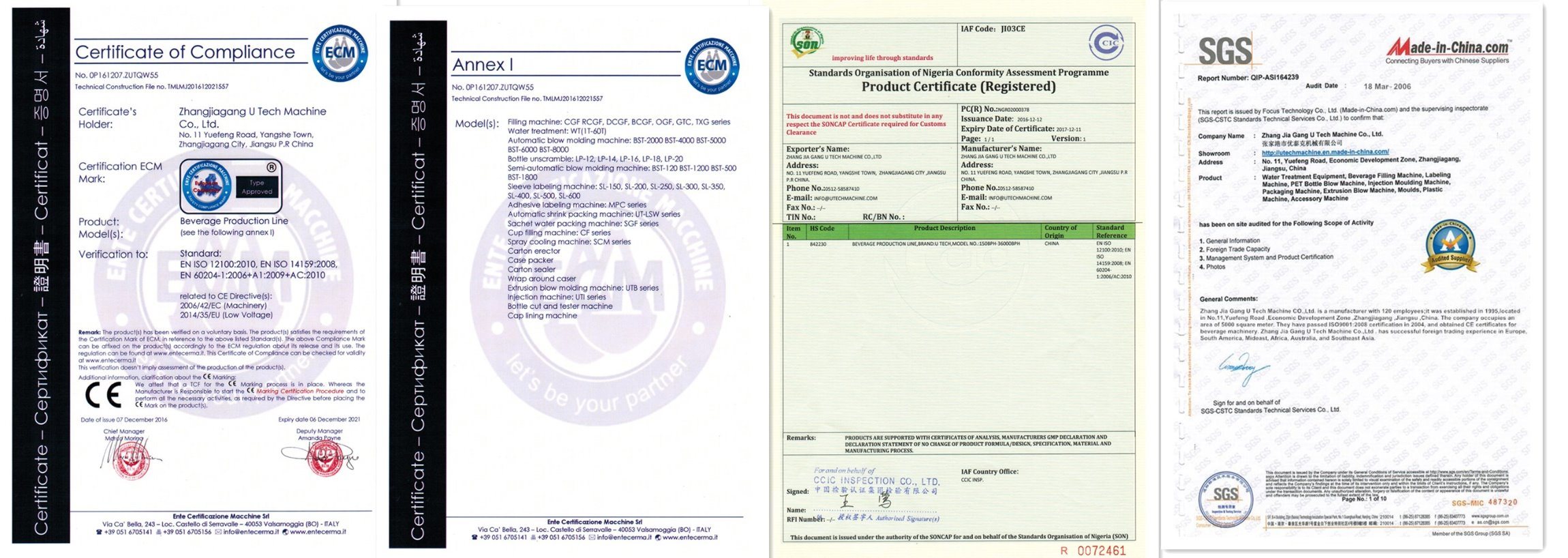

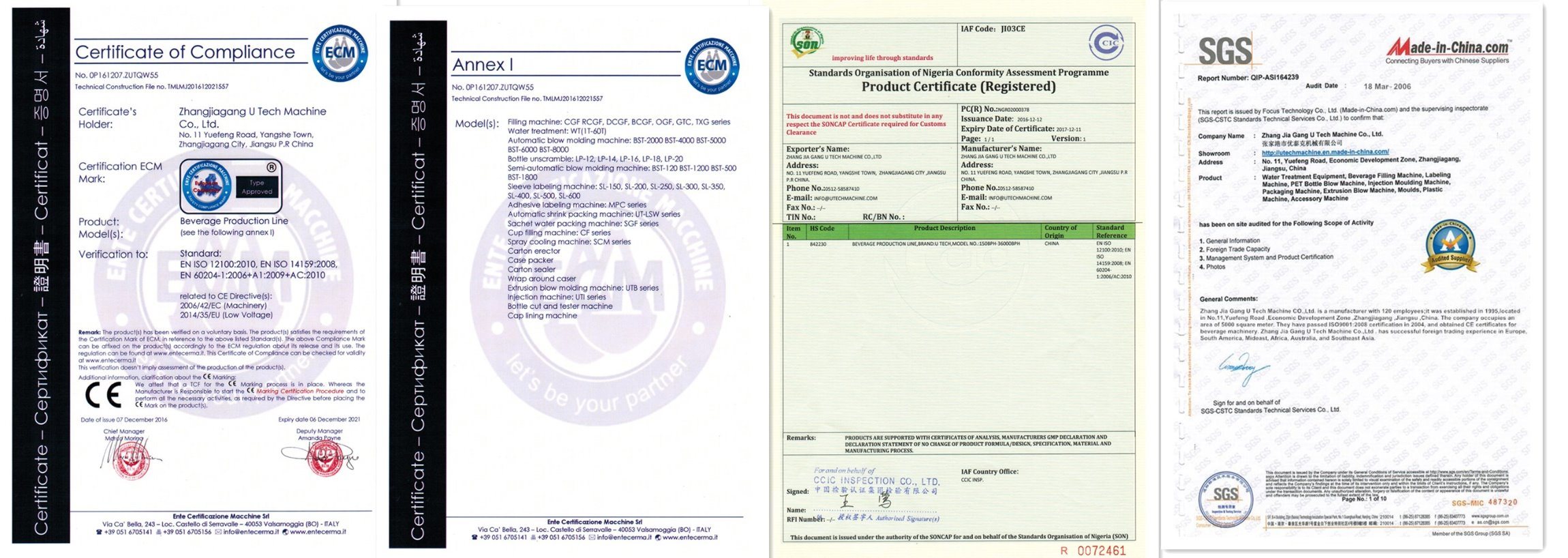

The wood material is according to the standard of the long-term shipping. Company Introduction: Zhangjiagang U Tech Machine Co., Ltd. is a manufacturer of filling machine and packing with well-equipped testing facilities and strong technical force. With a wide range, good quality, reasonable prices and stylish designs, our products are extensively used in beverage and other packing equipment.

Company Introduction: Zhangjiagang U Tech Machine Co., Ltd. is a manufacturer of filling machine and packing with well-equipped testing facilities and strong technical force. With a wide range, good quality, reasonable prices and stylish designs, our products are extensively used in beverage and other packing equipment.

Our products include: liquid filling machines (water, fruit juice/tea, carbonated drink, oil, alcohol, plant protein drink, etc.), barreled filling line (3-5 gallon) water treatment machines, labeling & packing machines, semi-automatic /full automatic PET bottle blowing machines, and injection molding machines, extrusion blow molding machines (PP/PE/PVC/PETG/PC...) and accessories for automation: leak tester machines, bottle bag packing machines, conveyor belts.

OUR SERVIVE:a. Well-trained & experienced staff are to answer all your inquiries in English and Chinese.

OUR SERVIVE:a. Well-trained & experienced staff are to answer all your inquiries in English and Chinese.

b.24 hours for engineer's response (all services part 5days in customer hand by Intl' courier).

c.2 Years guarantee

e. Your business relationship with us will be confidential to any third party.

f. Good after-sales service offered, please get back to us if you got any questions. FAQQ1:Are you a trading company or a manufactory?

A1:We are a manufactory,can give u best service .

Q2:What's your guarantee or the warranty of the quality if we buy your machines?

A2:We offer you high quality machines with 2 years guarantee . we will give u spare part free in 2 years

Q3:When can I get my machine after I paid?

A3:We will deliver the machines on time as the date we agreed both side.

Q4:How can I install my machine when it arrives?

A4:We will send our engineer to your side as soon as you get all your machines ready , for testing and teaching your technicians how to run the machines.

Q5:How about the spare parts?

A5:After we deal down all the things , we will offer you a spare parts list for your reference.

Welcome To Visit Zhangjiagang U Tech Machine Co.,Ltd!.contact: Rogers Wang M.B. +86 139 5113 3699

Zhangjiagang U Tech Machine Co., Ltd. is a manufacturer of beverage filling machine and packing with well-equipped testing facilities and strong technical force. With a wide range, good quality, reasonable prices and stylish designs, our products are extensively used in beverage and other packing equipment.

Our products include: Liquid filling machines (water, fruit juice/tea, carbonated drink, oil, alcohol, plant protein drink, etc. ), barreled filling line (: 1-5 gallon) water treatment machines, labeling & packing machines, semi-automatic /full automatic PET bottle blowing machines, and injection molding machines, extrusion blow molding machines (PP/PE/PVC/PETG/PC...) and accessories for automation: Leak tester machines, bottle bag packing machines, conveyor belts.

We can provide best services for customers, from plant layout, equipment manufacture and production line setup to operator training and best after-sales service. All machines are two years' service for all parts, 24 hours service (all spare parts in 5days will send to customer by Intl' courier). Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs. Now our products are exported to over forty countries and regions, including Russia, Ukraine, Saudi Arabia, Qatar, Venezuela, Colombia, Peru, Dominican, Chile, Malaysia, new Guinea and many other countries.

We welcome new and old customers from all walks of life to contact us!