Categories

Categories

| Price: | Negotiable/Ton |

|---|---|

| Min Order: | 1/Ton |

| Pay Type: | L/C,T/T,D/P,Western Union,Paypal |

| Prod Model: | 150d/3 |

|---|---|

| Usage: | Embroidery |

| Feature: | High Strength |

| Material: | 100% Polyester |

| Technics: | Open End/OE |

| Pattern: | Dyed |

| Type: | Fancy Yarn |

| Coarseness: | Medium Yarn |

| Structure: | Ring Spun Yarn |

150D/3 100% Trilobal Polyester Embroidery Thread for High-Speed Embroidery

MH embroidery thread includes 100% rayon embroidery thread, 100% polyester embroidery thread

Specification: 75d/2, 108d/2, 120d/2, 150d/2, 150d/3, 300d/2, 300d/3, 300d/, 300d/2*3, etc.

Annual capacity: 10000+ tons

Packing: 0.5kg to 1kg/big cone

Certificates: ISO9001, OEKO-TEX

It is manufactured in our thread factory, which has achieved ISO 9001 accreditation. In addition, the thread has achieved Oeko-Tex Standard 100 certification for environmental compliance in production.

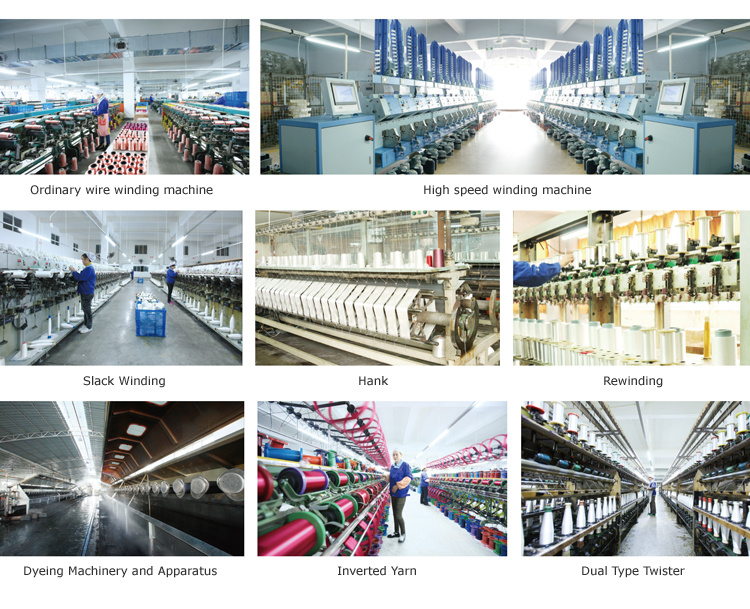

MH embroidery thread industry has a complete set of production line for spinning, dyeing, winding and shaping, working shop is around 20000 square meter5s with 400 skillful workers.

It is made of unique 100% trilobal polyester filaments by special processes. Compared with Rayon Embroidery Thread, it has unparalleled advantages such as high tenacity and good abrasion resistance. It is applicable for high-speed embroidery and generally used for embroidering items that will be laundered such as jeans, shoes, hats, etc.

Why choose us?

High strength - Our embroidery machine thread has excellent tensile strength which brings down chances of any breaking or fraying - fewer thread breaks allow you to complete your projects more efficiently and in a frustration-free manner. Long elongation of polyester also helps eliminate the chances of looping and puckering. These characteristics which impart high durability to the thread become extremely important when your clothing is expected to go through commercial laundering!

Color fast - Not only strength is important but even the color fastness of the thread when it comes to laundering, chlorine bleach or for that matter use of any harsh chemicals. Polyester is known for its ability to hold its colors really well when compared to other threads like rayon and is, therefore, a preferred choice of many as it doesn't easily shrink or bleed. This spool set for sure makes for an essential embroidery supply!

Ideal Choice: is perfect for company uniforms, work clothes, jeans, caps, linens and more. Even suitable for greasy restaurant and auto shop usage where the heavy laundering is required.

Colorfast to Chlorine: Polyester embroidery thread is tear resistant and colorfast to chlorine; high water temperatures and bleach do not compromise its integrity.

Bright and Vivid Colors: We offer a wide variety of bright and vivid colors that last through a large number of wash cycles.

Pantone Color Matching: We carry a large number of colors for Pantone color matching.

Long Lasting Durability: Retains its vibrancy even when subjected to tough industrial conditions.

Our polyester embroidery thread is used by many commercial embroiderers of industrial garments.

Fewer Thread Breaks: With our polyester embroidery thread you will experience far fewer thread breaks. Ideal for a multi-head environment where thread breaks can be costly.

Easy to Run: Many MH customers use polyester thread almost exclusively because of how easy it is to run on commercial embroidery machines. Whether you're running the largest 100+ head commercial embroidery machine operations or a smaller thread boutique, we can save you time and money with ease.

About us: Ningbo MH Thread Manufacturing Center has focused on sewing thread and embroidery thread manufacturing for almost 20 years. With more than 4 billion RMB annual sales volume now MH has three industry zones with 120000 square meters plant area, 1900 workers, poweful warehouse & logistics system, branches over the world, high standard machines and strict manufacturing management system. In this field, no one can do better than us.

Technical data

Denier | Tex (T) | Tickets Size | PLY | Average Strength (Cn) (g) | Elongation Min-Max (%) | Recommended Needle Size Singer Metric |

120D | 27 | 120 | 2 | 962 982 | 18-22 | 11 75 |