High Quality PP/Polypropylene Bcf Carpet Yarn

| Price: |

US $ 1800-2500/Ton |

| Min Order: |

1/Ton |

| Pay Type: |

L/C,T/T,Western Union,Paypal |

| Prod Model: |

CD-FY00228 |

| Yarn Type: |

FDY |

| Strength: |

5.0-7.5 GM Per Denier |

| Danier Range: |

100d-2000d |

| Usage: |

PP Woven Fabric |

| Material: |

100% Polypropylene |

| Feature: |

Abrasion-Resistant |

| Fiber Type: |

Filament |

| Pattern: |

Plain |

| Function: |

High Strength Fiber |

| Color: |

Optional |

| Structure: |

FDY |

Product Description

High quality PP/polypropylene BCF carpet yarn

BCF yarn is also called bulked continuous filament, which is made of PP chips added with color master batches, through extruding and melting of screw extruder, then processed with spinning, side air cooling, oiling, stretching, hot air variant, drum cooling, intermingling, winding and finally forms PP BCF bobbins.Technical Parameters | Product name | PP BCF Yarn | Raw material | Polypropylene |

| Linear Density | 800D-3000D | CV of density | <1 % |

| Deviation of density | <1 % | Intermingle Number (knots/meter) | Adjustable |

| Breaking tenacity | > 1.8g/d | CV of tenacity | 3% |

| Elongation of breaking | 60-90% | CV of elongation | 8% |

| Boiling water shrinkage | 3.2 % | Elongation of heat crimp | 25% |

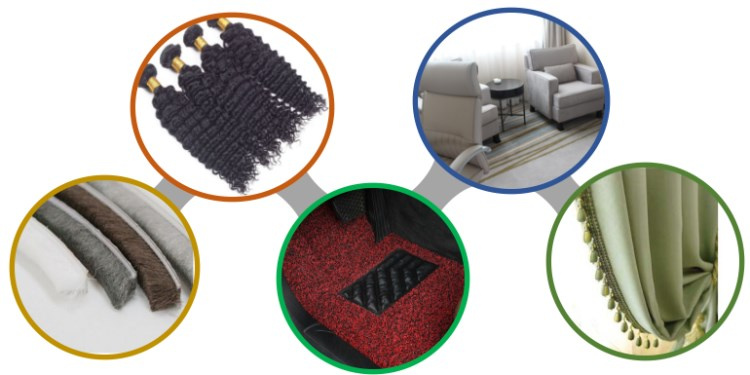

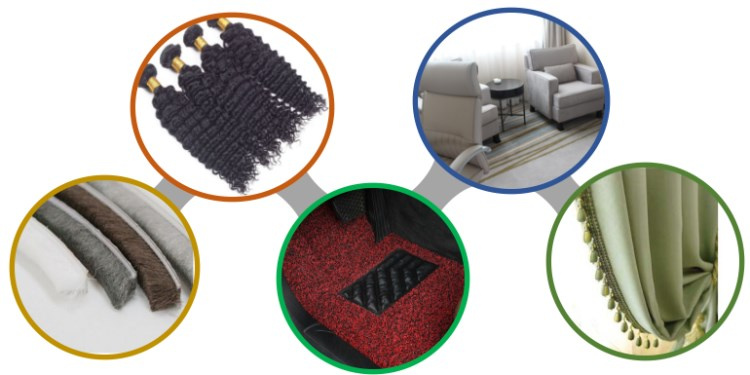

Applications The advantages of PP BCF Yarn are bright and durable colors, well effect of anti-static. Through delustering and twist-shaping, PP BCF Yarn could get the effect of imitation wool, which is applicable to the production of woven carpet. The carpet surface is extremely like the wool carpet with plump levelness and good resilience. The high quality of PP BCF Yarn and twist-shaping yarn is not only used for carpet weaving but also widely used for all kinds of decorative fabrics.

Established in 2005, Chuangda Group as a professional manufacturer, which is specialized in the research of renewable resources and the manufacturing of polypropylene filament (PP) yarn between 100D to 2000D, PP Air-jet Texturing Filament Yarn (ATY), Chenille Yarns, PP color master batch, PP functional master batch, polypropylene (PP) fabrics and FIBC bags (also called jumbo bag, big bag, ton bag, super sack) etc.

Owning the whole production chain from design, R&D to processing, Chuangda introduced the most advanced equipments for granulating, drawing, circular weaving, cutting, printing, sewing, packaging and also testing. We always supply our customers with the best quality but favorable price products.

To meet the increasing market needs of FIBC bags, Chuangda extended another production site in Xiangshui of Yancheng, a northern city in Jiangsu, and also established an individual trading company to supply better service for global customers.

Now there are totally three companies under Chuangda Group:

1. Changzhou Chuangda Renewable Resources Technology Co., Ltd. (established in 2005)

2. Jiangsu Chuangda New Materials Co., Ltd. (established in 2012),

3. Chuangda Plastic Industry Co., Limited (established in 2016)

We stick to the principle of "quality first, service first, continuous improvement and innovation to meet the customers" for the management and "zero defect, zero complaints" as the quality objective.

We're pleased to get your Inquiry and we will come back to you as soon as possible.

More >

Other Products with This Manufacturers