| Prod Model: |

DB-50A |

| Model: |

dB-50A |

| Volume Of Bag: |

5-50 Kg |

| Speed: |

300 Bags Per Hour |

| Sealing Type: |

Heat Sealer; Sewing Closer |

| Threads Of Sewing: |

2 Threads; 4 Threads |

| Power Of Heat Sealer: |

0.37 Kw, 220V/50Hz |

| Power Of Belt Conveyor: |

0.37 Kw, 380V/50Hz; Three Phase |

| Length Of Conveyor: |

2.7m Long |

| Warranty: |

One Year |

| Keywords: |

Rice Packing Machine |

| Type: |

Weighing-type Filling Machine |

| Automatic Grade: |

Automatic |

| Material Type: |

Granular |

| Filling Valve Head: |

Single-Head |

| Feed Cylinder Structure: |

Single-Room Feeding |

| Filling Principle: |

Atmospheric Pressure |

| Packaging Container Lifting Structure: |

Pneumatic Lifting |

| Structure: |

Rotary |

| Packaging Type: |

Bag |

| Packaging Material: |

Plastic |

| Dosing Device: |

Storage Tank |

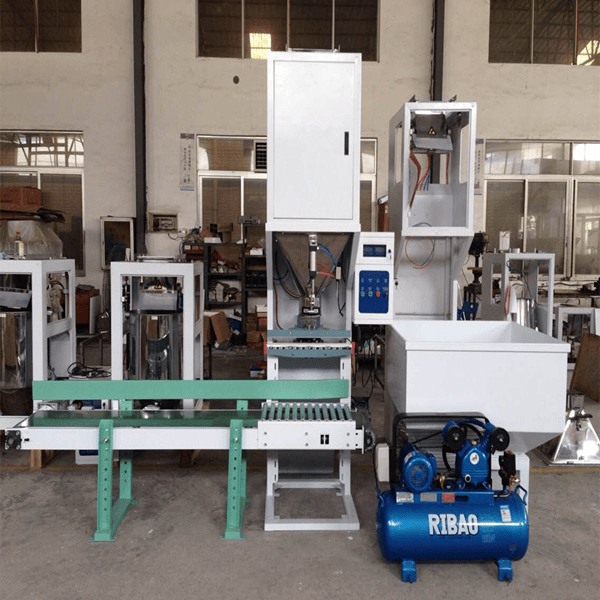

Product Description

Rice Packing Machine with Sewing Machine Automatic Package Machine

Range of Application:

Rice Packing Machine with Sewing Machine Automatic Package Machine is suitable for the quantitive packaging of granules in food, grain, fodder, Sugar making, pellet packing and chemical industry,etc.

Technical Data:

| Model Name | DB-1 | DB-5 | DB-25 | DB-50 | DB-100 |

| Packing Range | 0.2-1kg | 1-5kg | 2.5-25kg | 5-50kg | 10-100kg |

| Packing Error | 0.2%F.S | 0.2%F.S | 0.1 %F.S | 0.1 %F.S | 0.1 %F.S |

| Packing Speed | 300-500 bags/h | 300-500 bags/h | 300-420 bags/h | ≥300 bags/h | ≥ 300 bags/h |

| Division Value | 2g | 5g | 10g | 20g | 20g |

| Power | AC 220V 50Hz |

| Air Supply | 0.4-0.8 MPa |

| Machine Dimension | 1725 x 620 x 710

(mm) | 1890 x 620 x 710

(mm) | 2450 x 650 x 715

(mm) | 2560 x 650 x 715

(mm) | 2960 x 730 x 775

(mm) |

| Actuator | Pneumatics |

| Accuracy Class | X(0.2) X(0.1) |

Features:

1) New controller with high precision can display the total weight, number of package, easy operation.

2) The adaptive software, having the function of automatic control parameters setting, automatic drop revising, over-weight warning and auto-diagnosis.

3) Wide packing range, it can match well with conveyor and sewing machine

4) Adopt imported sensor, pneumatic actuator, easy maintenance and non-pollution.

5) The main materials body is carbon steel, with painted plastic.And material contact part is stainless iron, corrosion resistance, long service life

6) Communication interface can be offered if need, realization of data communication with PC

Zhengzhou Leabon Machinery Equipment Co., Ltd. is a professional supplier for separating machinery, pellet machine, briquette machine, pellet stove, wood crusher, sawdust dryer, and pellet making line, briquette making line, combining development, design, manufacture, sales and services. It enjoys professional production technology, superior manufacturing equipment and good testing means.

In order to meet different needs of customers, we have been constantly developing and improving product technology, quality, and process automation and after-sale service. Our unremitting efforts for years have bought us great trust from customers and our products enjoy fast sales abroad.

We don' T aim at maximizing profits, don' T aim at maximizing assets scale, and don' T lower quality to cater to markets at low price. We hold the management tenet: Guaranteed quality, quality goods, morality first, credit foremost. We take customers' Needs as our developing basis and take customers' Satisfaction as our goal. Reasonable levels of prices can meet different needs. We have been in the practice of quick serve, joining hands with personages of various circles to make sincere operation and common development!