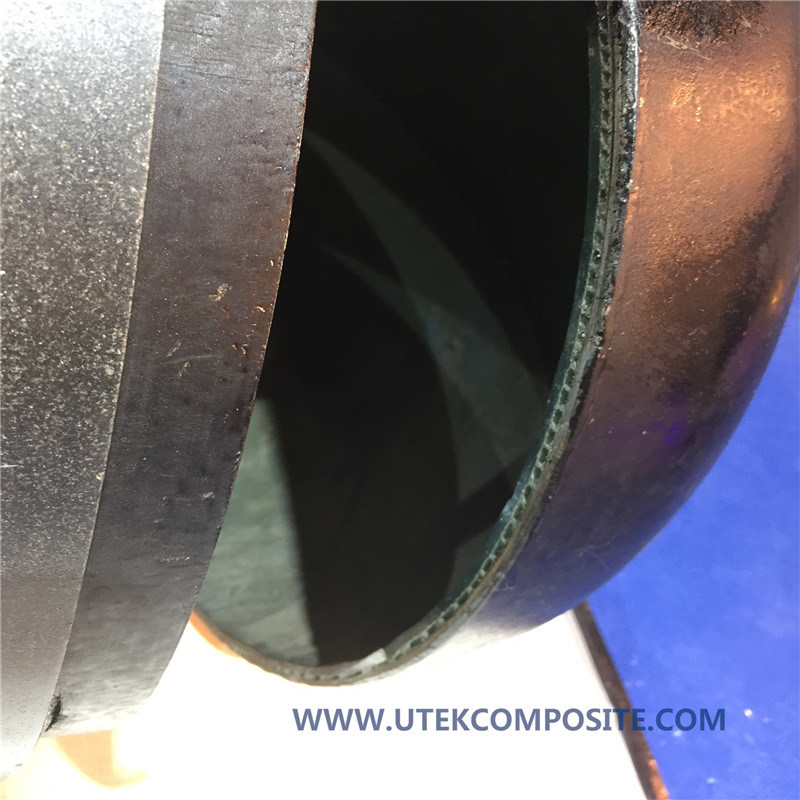

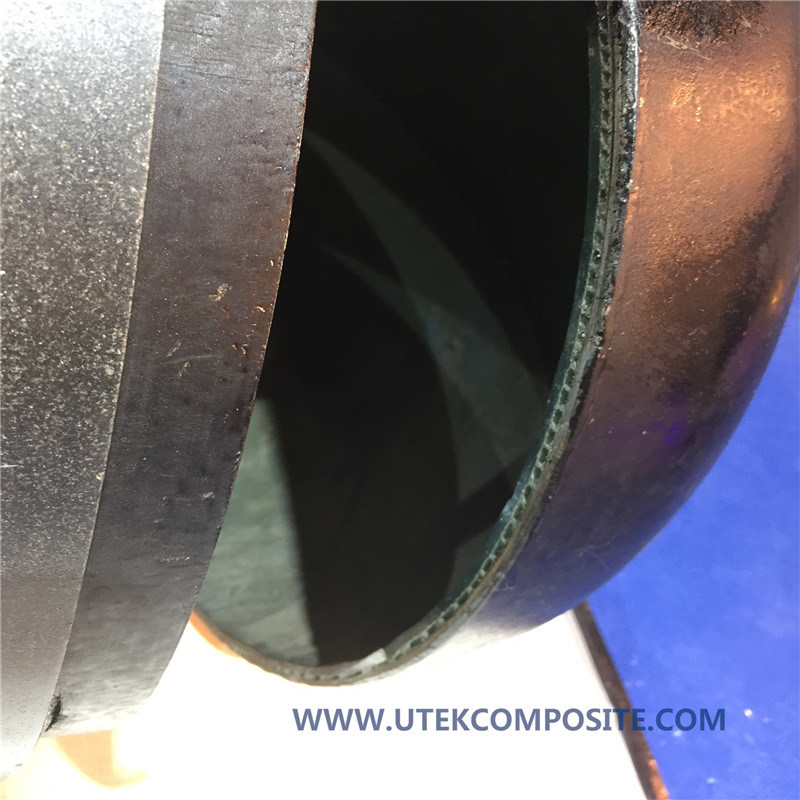

It is woven from E glass yarn and consists of two surfac(deck) layers connected together by vertical links(piles).These links are woven together with the surface layers thus forming an integrated sandwich sructure.When a thermoset resin such as ployester or epoxy is added to the 3D glass fabric and lightly rolled,the surface fabric is impregnated with the resin.Capillary action also wets out the connecting links,so that when the fabric rebounds to its full height a hollow core is formed(much like the tree trunks in a forest).This one-step process forms a sandwich laminate that offers excellent strength,stiffness,light weight and durability.

During impregnation the fabric is compressed but immediately rebounds to its original height,resulting in a lightweight sandwich laminate.This sandwich laminateforms the basis of the most technology-advanced applications.The integral sandwich concept in which core and faces are integrated to build sandwich laminates from 3 to 22 mm.

FEATURES:

Light weight, High stiffness

Simple and effective lamination process

Outstanding performance in resistance to delamination

Easy to make an angle curve

Hollow structure

High design-versatility

APPLICATIONS:

Double wall storage tanks, chemical storage tanks, aircraft, railway, automotive, decorative wall panels, billboard, industrial roofing and various applications in different fields.

Technical Data Sheet |

| Fabric type | | | | E3P | E5P | E8P | E10P | E12P | E15P | E18P | E22P |

| Thickness |

| Core | | mm | | 3.0 | 5.0 | 8.0 | 10.0 | 12.0 | 15.0 | 18.0 | 22.0 |

| Face | | mm | | 0.4 | 0.4 | 0.4 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 |

| Weight |

| Fabric | | kg/m2 | | 0.78 | 0.83 | 0.92 | 1.34 | 1.42 | 1.51 | 1.58 | 1.74 |

| Laminate | | kg/m2 | | 1.65 | 1.76 | 1.95 | 2.84 | 3.01 | 3.20 | 3.35 | 3.60 |

| Mechanical properties |

| Compressive strength | ASTM 365 | N/mm2 | Average | 11.2 | 3.04 | 2.25 | 1.01 | 0.941 | 0.871 | 0.527 | 0.421 |

| Shear strength | ASTM 273 | N/mm2 | Average | 4.65 | 1.35 | 1.42 | 0.352 | 0.338 | 0.249 | 0.188 | 0.161 |

| Bending strength | ASTM 393 | N/mm2 | Average | 144 | 89.8 | 71.7 | 47.4 | 40.2 | 21.7 | 18.5 | 16.8 |

| Thermal property |

| Thermal conductivity | GB/T10294-1988 | W/(m.k) | | 0.07 | 0.07 | 0.07 | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 |

NOTE: The technical parameters are attained on the condition that the ratio of 3D perform to designated resin is 1:1.1, what's more, resins with different species, brand and different dosages makes a difference to the final mechanical properties. The mechanical performance in weft direction is better than those in warp direction.

| CHANGZHOU UTEK COMPOSITE COMPANY CO.,LTD |

|

| COMPANY INTRODUCTION: |

| Company Name | CHANGZHOU UTEK COMPOSITE CO.,LTD |

| Address | Fuhanyuan 1-814,Taihu Road,Changzhou,Jiangsu,China |

| Contact Person | Name | Tel | |

| Manger | Gong Xiaojun | 0086 13357899376 | |

| Manger | Irene Xi | 0086 13961156380 | |

| Business Condition | Manufacture | Trading |

| Consititution of company | Pvt.Ltd |

| Annual turnover | USD10,000,000 |

| Company Occupy Areas(M2) | 3000M2 |

| Shower room Occupy Areas(M2) | 200M2 |

| website | www.utekcomposite.com |

| http://utekcomposites.en.made-in-china.com/ |

| Mainly Customer & Marketing | Europe,Asia,America,Middle East |

| Mainly Product | Fiberglass chopped strand mat (powder and emulsion), stitch mat, combo mat, uni-direction and biaxial fabric, RTM core mat, woven roving, special products like Ar-glass roving, chopped strand, thin fiberglass fabric, SMC(sheet molding compound), fiberglass/polyester geogrid and geocomposite. fiberglass mica fabric for insulation. |

|

|

|

| Sales Team | 15(University Graduates) | Product Team | 150 |

| Research & Development Team | 12 | QC Team | 8 |

| Certificate | ISO 9001 ,ISO 14001 ,SGS |

Give us a chance, and we' ll return you with satisfaction.

Changzhou Utek Composite Co. Is committed to provide tailor-made service to customers with various requirements. We pay attention to needs of customers who adopt different production technologies like hand lay up, pultrusion, winding, close molding… Changzhou Utek is customer-oriented, from sales to production, in each step.

With many years of experiences in composite industry, we utilize our good working knowledge to develop, manufacture and distribute materials for:

Composite Reinforcement

1. Fiberglass cloth for surfboard: Standard and warp enhanced, have a lot of export to Australia, Indonesia, Brazil, Argentina…

2. Sandwich mat with PP core for RTM process: Exported to Russia, Malaysia, Spain, used to make big size road plate, cooling tower…

3. Fiberglass chopped strand mat: Big roll and wide width available, good quality of light weight mat for auto headliner such as 100g, 120g, 150g

4. Other reinforcement material such as stitch mat, combo mat, uni-direction and biaxial fabric, woven roving, Ar-glass roving, chopped strand

Chemicals:

1. SMC/BMC: Experienced in SMC for water tank, electric meter box, manhole cover. Have a lot of export to Saudi Arabia, South Africa, Malaysia

2. UP resin: Exported to Thailand, Chile, Nigeria

GRC: Ar-glass spray up roving, Ar-glass chopped strand, exported to Saudi Arabia, Egypt, Indonesia…

Geosynthetics: Fiberglass/polyester geogrid, paving grid, drainage geonet for landfill

We' Re one step source for composite reinforcements. Give us a chance, and we' Ll return you with satisfaction.