| Prod Model: |

ELTM1080 with PP |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Max Width: |

240cm |

| Area Weight: |

1080GSM |

| Layer: |

4 Layers |

| Consturction: |

0/90 Direction Biaxial PP Combi Mat |

| Roving In 0 Direction: |

300GSM |

| Roving In 90 Direction: |

300GSM |

| PP Weight: |

180GSM |

| Mat Weight: |

300GSM |

| Resin Compatibility: |

up/Ve |

| Function: |

Fireproof |

| Certification: |

ISO |

| Type: |

Fiberglass Fabric |

Product Description

1080GSM No crimp biaxial 0 and 90 orientation fiberglass mat for necellecove, Fiberglass combo mat has allowed for faster fabrication of parts with better physical and mechanical properties. Parts made from these reinforcements have LED to cost effective solutions for a variety of applications including Necellecove, marine, transportation, infrastructure, sports and recreation and aerospace.

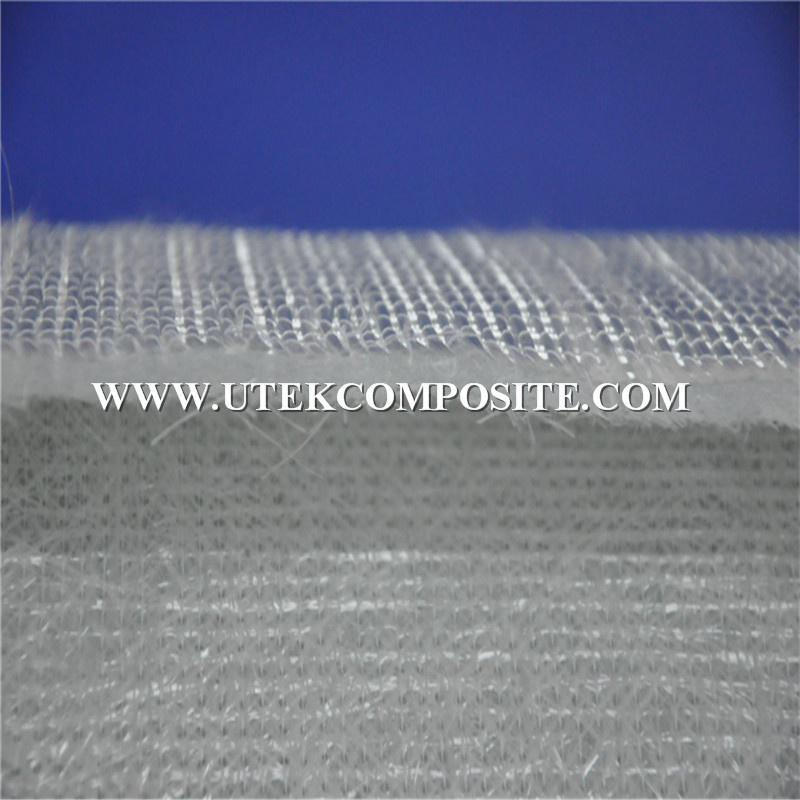

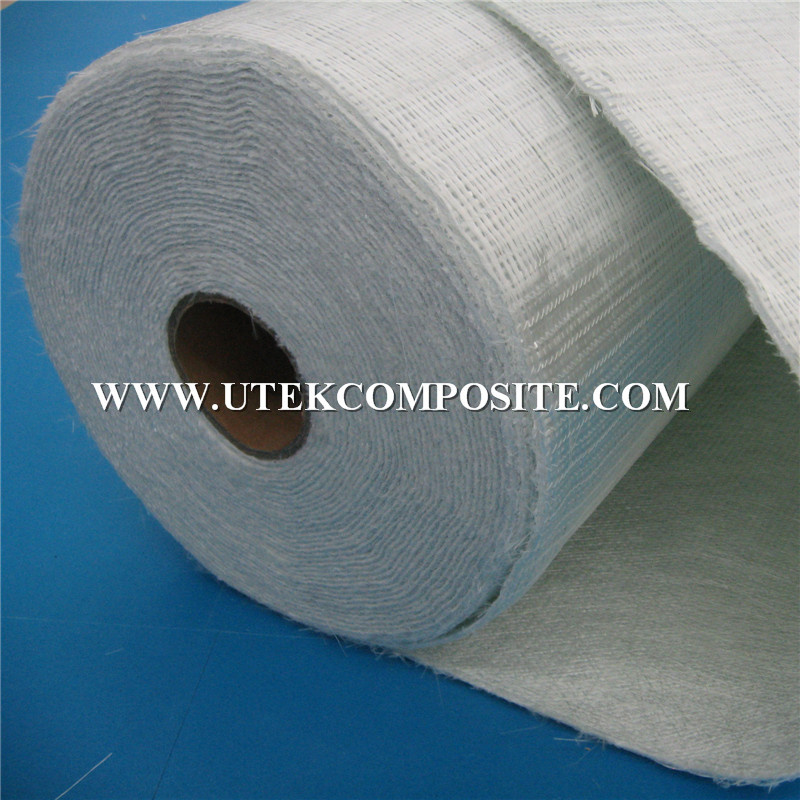

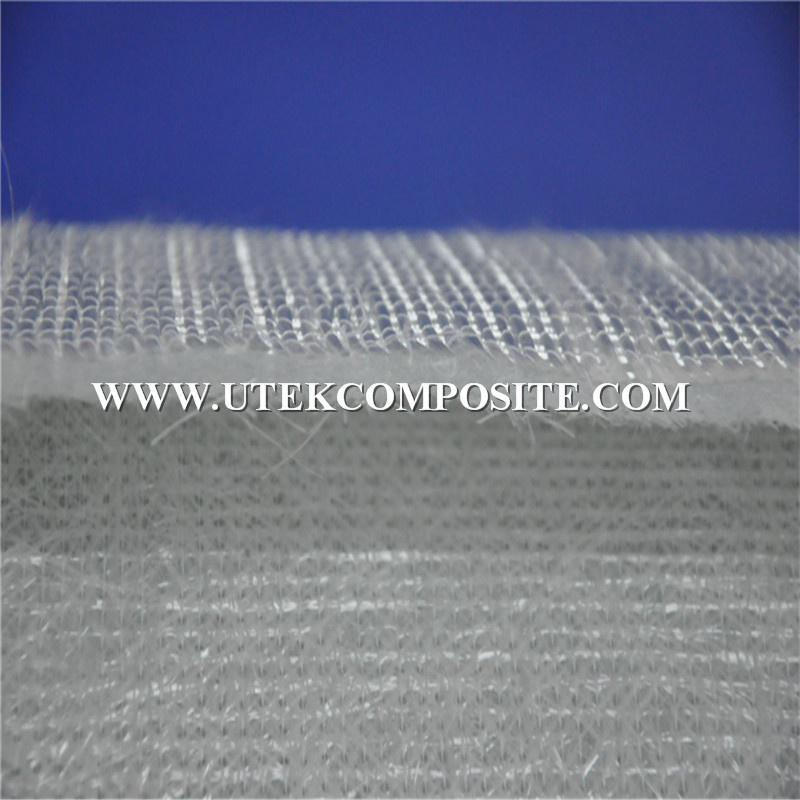

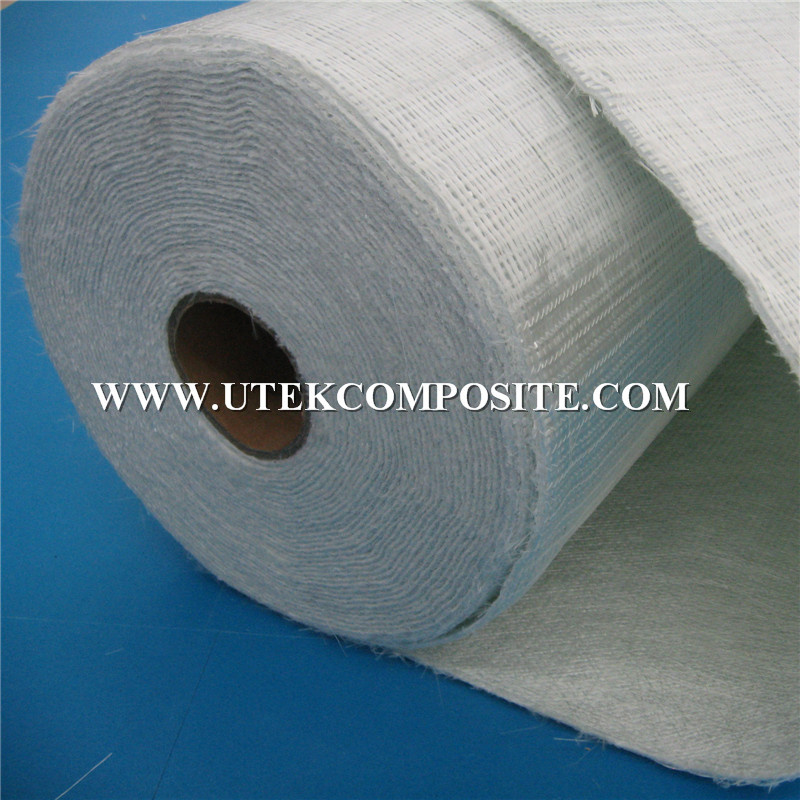

Combomat with PP 1100 is a 1080G/M2 stitch bonded composite reinforcement fabric containing a PP layer inside the fabric, the fabric consists of 4 layers: Direct roving in 0 degree and 90 degree directions, a PP non-woven layer in the middle, and chopped strands on the outside of the PP layer.

It is no any binder, no intersections of weft and warp, no crimp, so characterized by its optimal mechanical performance.

The specification is 600GSM roving in 0/90 degree direction, 300GSM mat. PP in the middle.

It is suitable for vacuum.

Technical Data: | Id | Layer | Unit | 1 | 2 | 3 | 4 | Stitching |

| 2.1 | Fibre orientation | Degrees | 0±3 | 90±3 | Non-woven | CS | |

| 2.2 | Nominal area weight | g/m² | 300 ±5% | 300 ±5% | 180 ±5%(177) | 300 ±5%(602) | 10 |

| 2.3 | Roving/yarn weight | tex | 1200 ±60 (1230) | 1200 ±60

(1233) | - | 33 subtex

(33.7) | 150 dtex

(148) |

| 2.5 | Av. filament diameter | mm | 17(17) | 17(17) | - | 13(13) | Polyester(textured) |

| 2.6 | Roving type | - | Direct roving

(Yes) | Direct roving

(yes) | - | Assem-bled roving

(yes) | |

| 2.7 | Resin compatibility | | UP, VE | UP, VE | | UP, VE | |

| 2.8 | Stitching type | | | | | | Tricot, chain |

| 2.9 | Space between needles | | | | | | Gauge 7 |

| 2.10 | Stitching length | | | | | | 4.0mm |

Packing & Storage:Each roll covering by polyethylene plastic bag,then placed into carton and set on pallet,or set on pallet directly.The pallet shall no be higher than 2 layers.

Product shall be placed under dryness condition and shall no be open the covering membrane until applying.

Picture of Product:

| CHANGZHOU UTEK COMPOSITE COMPANY CO.,LTD |

|

| COMPANY INTRODUCTION: |

| Company Name | CHANGZHOU UTEK COMPOSITE CO.,LTD |

| Address | Fuhanyuan 1-814,Taihu Road,Changzhou,Jiangsu,China |

| Contact Person | Name | Tel | |

| Manger | Gong Xiaojun | 0086 13357899376 | |

| Manger | Irene Xi | 0086 13961156380 | |

| Business Condition | Manufacture | Trading |

| Consititution of company | Pvt.Ltd |

| Annual turnover | USD10,000,000 |

| Company Occupy Areas(M2) | 3000M2 |

| Shower room Occupy Areas(M2) | 200M2 |

| website | www.utekcomposite.com |

| http://utekcomposites.en.made-in-china.com/ |

| Mainly Customer & Marketing | Europe,Asia,America,Middle East |

| Mainly Product | Fiberglass chopped strand mat (powder and emulsion), stitch mat, combo mat, uni-direction and biaxial fabric, RTM core mat, woven roving, special products like Ar-glass roving, chopped strand, thin fiberglass fabric, SMC(sheet molding compound), fiberglass/polyester geogrid and geocomposite. fiberglass mica fabric for insulation. |

|

|

|

| Sales Team | 15(University Graduates) | Product Team | 150 |

| Research & Development Team | 12 | QC Team | 8 |

| Certificate | ISO 9001 ,ISO 14001 ,SGS |

Give us a chance, and we' ll return you with satisfaction.

Changzhou Utek Composite Co. Is committed to provide tailor-made service to customers with various requirements. We pay attention to needs of customers who adopt different production technologies like hand lay up, pultrusion, winding, close molding… Changzhou Utek is customer-oriented, from sales to production, in each step.

With many years of experiences in composite industry, we utilize our good working knowledge to develop, manufacture and distribute materials for:

Composite Reinforcement

1. Fiberglass cloth for surfboard: Standard and warp enhanced, have a lot of export to Australia, Indonesia, Brazil, Argentina…

2. Sandwich mat with PP core for RTM process: Exported to Russia, Malaysia, Spain, used to make big size road plate, cooling tower…

3. Fiberglass chopped strand mat: Big roll and wide width available, good quality of light weight mat for auto headliner such as 100g, 120g, 150g

4. Other reinforcement material such as stitch mat, combo mat, uni-direction and biaxial fabric, woven roving, Ar-glass roving, chopped strand

Chemicals:

1. SMC/BMC: Experienced in SMC for water tank, electric meter box, manhole cover. Have a lot of export to Saudi Arabia, South Africa, Malaysia

2. UP resin: Exported to Thailand, Chile, Nigeria

GRC: Ar-glass spray up roving, Ar-glass chopped strand, exported to Saudi Arabia, Egypt, Indonesia…

Geosynthetics: Fiberglass/polyester geogrid, paving grid, drainage geonet for landfill

We' Re one step source for composite reinforcements. Give us a chance, and we' Ll return you with satisfaction.